1. General Discussion

1.1 Background

1.1.1 History

This wipe sampling method was

developed to provide a uniform and practical means of taking wipe

samples for 1,6-hexamethylene diisocyanate (HDI). The sampling of HDI

on surfaces was performed using Ghost Wipes (Environmental Express).

The Ghost Wipe was chosen for its durability and its use in surface

sampling of other analytes. The samples are analyzed following the

procedure in OSHA Method 421,

using high performance liquid chromatography (HPLC). Glass plates were

used as the ideal surface to check the surface sampler removal

efficiency. The use of a surface that approximates an ideal surface

(extremely smooth and non-porous) minimizes the effect of the surface

on the evaluation of the media. No interactions between the glass

plate and HDI were found. In this evaluation, the media are pre-wetted

with a solution of 50:50 isopropanol:water. After sampling, the

samples were immediately placed in vials containing 5 mL of a

derivatizing reagent solution of 50:50 dimethyl sulfoxide (DMSO):ethyl

acetate and 0.025 M 1-(2-pyridyl) piperazine (1- 2PP). The

derivatizing reagent (1-2PP) reacts with HDI by attaching a

chromaphore to the molecule. This improves the analytical sensitivity

of the method. Also, without the derivatizing reagent, the HDI will

begin to hydrolyze or polymerize and the HDI on the sample will be

lost. A derivatizing reagent solution of 0.025 M 1-2PP in acetonitrile

was initially used. However, other isocyanates that were to be

evaluated did not go into solution in this reagent. To make this

method as uniform and practical as possible for other isocyanate

sampling methods, the derivatizing reagent with DMSO and ethyl acetate

as solvent was used. A study was conducted to investigate the reaction

of HDI with the alcohol and the water in the wetting solution prior to

being derivatized. It was determined that the time interval, from

beginning collection of the sample, until the sample is placed in

contact with the derivatizing reagent should not exceed three minutes.

(Section 4.9)

1.1.2 Toxic effects (This section is for

information only and should not be taken as the basis of OSHA

policy.)

Many dermal exposure studies on animals describe

the ability of HDI to cause contact sensitization or direct irritation

to the skin of laboratory animals.2

Respiratory hypersensitivity has been induced by exposure of

diisocyanates to the skin of laboratory animals.3,

4,

5,

6

Human skin exposure to diisocyanates has resulted in erythema,

eczematous dermatitis, contact eczema characterized by follicular

papules and dermal sensitization.7

A procedures for conducting urinalysis for 1,6-hexamethylene diamine

as an indicator of the biological metabolite of HDI has been

published.9

1.1.3

Workplace exposure

Occupations with the greatest

potential for exposure to HDI are painters and paint spraying machine

operators, aircraft engine mechanics, and aircraft machinists. Other

occupations with potential for exposure to HDI include construction

laborers, chemical technicians, mixing and blending machine operators

in the chemical industry, plumbers, pipe fitters, steam fitters, metal

plating machine operators, miscellaneous machine operators in the

aircraft equipment industry, and production workers and supervisors in

the fabricated structural metal industry.8

1.1.4

Physical properties and descriptive information10

| CAS number: |

822-06-0 |

vapor pressure (mmHg): |

0.05 |

| IMIS number: |

137711 |

molecular weight: |

168.20 |

| flash point (OC): |

135ºC |

boiling point: |

255ºC |

| melting point: |

-67ºC |

odor: |

pungent |

| appearance: |

Pale yellow liquid |

synonyms: |

1,6-diisocyanatohexane, HDI |

| molecular formula: |

OCN-(CH2)6-NCO |

solubility: |

poorly soluble in water, |

| specific gravity: |

1.04 g/mL |

|

reacts slowly with water |

| LD50, rabbit,

dermal: |

570 µg/kg12

|

|

|

| SD50

(sensitization dose) mouse, dermal: 0.088 mg/kg |

| LOAEL (Lowest

observable adverse effects level), guinea pig, dermal: 0.1

mg |

This method was evaluated according to the OSHA SLTC

"Evaluation Guidelines for Surface Sampling

Methods".13

The Guidelines define analytical parameters, specify required laboratory

tests, statistical

calculations and acceptance criteria. The analyte

surface concentrations throughout this method are based on the evaluated

sampling area and analytical concentration parameters.

1.2 Limit defining parameters

1.2.1 Detection limit of the overall procedure

The

detection limit of the overall procedure is 0.29 µg per sample. This

is the smallest

amount of HDI spiked on the wipe sampler that will

give a detector response that is

significantly different from the

response of the wipe sampler blank. (Section 4.1 )

1.2.2

Reliable quantitation limit

The reliable quantitation limit is

0.96 µg per sample. This is the amount of HDI spiked on

the wipe

sampler that will give a detector response that is considered the

lower limit for a

precise quantitative measurement. (Section

4.1)

1.2.3 Recovery effects of storage

The recovery of

HDI from spiked samples used in a 15-day storage test remained

above

88.6% when the samples were stored at 22 °C. (Section

4.2)

1.2.4 Surface sampler removal efficiency

The

removal efficiency of Ghost Wipe moistened with 0.5 mL of wetting

reagent for HDI

spiked at the target concentration of 340.0

µg/100cm2 is 68.3%. This was the percentage

of HDI that

was removed from a glass plate surface, spiked at the target

concentration.

(Section 4.3)

1.2.5 Sampling

reproducibility and analytical reproducibility

Six glass plate

surfaces were spiked at the target concentration. Chemists, other than

the

one developing the method, conducted sampling on the glass

plate surfaces as described

in Section 2. The test was repeated

with a second chemist performing the sampling. The

first chemist

was able to achieve a removal efficiency of 60.7%. The second chemist

was

able to achieve a removal efficiency of 55.5%. (Section

4.5.1)

Six samples spiked at the target concentration by

liquid injection were submitted for

analysis by the OSHA Salt Lake

Technical Center. The samples were analyzed according

to a draft

copy of this procedure after 22 days of storage at 22 °C. The average

analytical

result was 111% of theoretical. (Section

4.5.2) 2. Sampling

Procedure

All safety practices that apply to the work area being

sampled should be followed. The sampling should

be conducted in such

a manner that it will not interfere with work performance or safety. The

derivatizing reagent solution contains DMSO. DMSO is readily absorbed by

the skin and is an excellent vehicle to transfer contaminants dissolved

in it through the skin barrier. Skin contact with the derivatizing

solution containing DMSO should be avoided.

2.1 Apparatus

2.1.1 Chemical resistant gloves; samples are collected

using firm hand pressure to wipe the

sampling medium across a

surface. Wear a clean pair of gloves for each sample. The

gloves

selected are to be resistant to penetration of the chemical being

sampled and any

other chemicals expected to be present. Nitrile

gloves were used for sampling

1,6-hexamethylene diisocyanate based

on a review of glove manufacturer's chemical

resistivity and

degradation information.

2.1.2 Labeled 20-mL scintillation

vials with PTFE lined caps, one for each sample, each

containing 5

mL of derivatizing reagent solution.

2.1.3 Ghost Wipes, dry,

catalog number SC4050, Environmental Express, Mt. Pleasant,

S.C.

2.1.4 Disposable pipette and bulb, capable of delivering

0.5 mL. Non-sterile graduated pipette,

catalog no. 13-711-9A,

Fisher Scientific, Fair Lawn, NJ.

2.1.5 Optional steel or

plastic measuring tape or disposable Sampling Template 10 × 10

cm,

catalog number 1010, Environmental Express, Mt. Pleasant,

S.C. 2.2 Reagents

2.2.1 Water, HPLC grade. A Millipore Milli-Q system was

used to prepare the deionized water (DI water) for this

evaluation.

2.2.2 Isopropanol, HPLC grade, Lot No. 001456,

Fisher Scientific, Fair Lawn, NJ.

2.2.3 Ethyl acetate, HPLC

grade, Lot No. 924366, Fisher Scientific, Fair Lawn, NJ.

2.2.4

Dimethyl sulfoxide (DMSO), HPLC grade, Lot No. BB965, Baxter,

Muskegon, MI.

2.2.5 1-(2-Pyridyl) piperazine (1-2PP), Lot No.

09914JU, Aldrich, Milwaukee, WI.

2.2.6 Wetting reagent, 50:50

isopropanol:deionized water (DI) water.

2.2.7 Derivatizing

solution, 50:50 ethyl acetate:DMSO with 0.025 M 1-2PP. 2.3

Shipping media and reagents to the sampling site and reagent

preparation

The media are received from the supplier in packages

containing 100 wipes per package. Wear clean gloves and remove a

sufficient number of wipes to perform the sampling. Remember to include

extra wipes to serve as blanks. Place the wipes in a 5 × 7 in.

recloseable polyethylene zipper bag. Place the remaining wipes in a

large recloseable polyethylene zipper bag. The selected wipes can now be

shipped or taken to the workplace for sampling.

Place a

disposable pipette and bulb, capable of delivering 0.5 mL in a small

recloseable polyethylene zipper bag and ship with the wipe

media.

Prepare the 50:50 isopropanol:DI water wetting

reagent that is needed to moisten the wipe prior to sampling. Place 50.0

mL of the wetting reagent in a labeled bottle and cap

securely.

Prepare the derivatizing solution that is combined with

the wipe sample after sampling. The derivatizing solution consists of

50:50 ethyl acetate:DMSO with 0.025 M 1-2PP.

Place 5.0 mL of

derivatizing solution in each scintillation vial, one for each sample.

Cap the vials securely.

Following current Department of

Transportation (DOT) regulations. Pack the bottle containing the wetting

reagent and the vials containing the derivatizing solution in a shipping

container and label it.

2.4 Sampling technique

Label

a sufficient number of vials containing the derivatizing solution with a

unique number, for the projected sampling needs. Wear clean unpowered

gloves when handling the media.

Prepare a diagram of the area or

rooms to be wipe sampled along with the locations of key

surfaces.

Wear a new pair of clean gloves for each sample to

prevent contamination of future samples as well as oneself. The gloves

selected are to be resistant to penetration of the chemical being

sampled and any other chemicals expected to be present. Nitrile gloves

are recommended for sampling 1,6-hexamethylene diisocyanate based on a

review of glove manufacturer's chemical resistivity and degradation

information.

Record the sample vial number and the location where

the sample is taken. Withdraw a Ghost Wipe from the zipper bag with your

gloved fingers or clean tweezers. Use the disposable pipette to moisten

the medium with 0.5 mL of the wetting reagent.

Depending on the

purpose of the sample, it may be useful to determine the surface loading

of the contamination (e.g., in micrograms of analyte per area). For

these samples, it is necessary to determine the area of the surface

wiped (e.g., 100 cm2). To make this measurement, hold the

measuring tape above the surface (without touching) or place the

disposable sampling template on the surface before sampling. This would

not be necessary for samples taken to simply show the presence of the

contaminant.

The amount of time, from beginning to collect the

sample, until the sample is placed in the vial containing the

derivatizing reagent, should not exceed three minutes. (Section

4.9)

Firm pressure should be applied when wiping. Start at the

outside edge and progress toward the center making concentric squares of

decreasing size. Fold the medium with the contaminant side inward and

repeat.

Without allowing the medium to come into contact with any

other surface, fold the medium with the exposed side inward. Place the

medium in a sample vial containing the derivatizing solution, cap and

shake vigorously for one minute. Place a number corresponding the sample

to the location on the diagram. Include notes with the sketch giving any

further description that may prove useful when evaluating the sample

results (e.g., a description of the surface sampled, such as: pencil,

doorknob, safety glasses, lunch table, inside respirator, employee's

names, etc.).

Submit at least one blank wipe medium, treated in

the same fashion as the wipe samples, but without wiping.

Record

sample location, employees names, surface area (if pertinent), work

description, PPE, and any other necessary information, along with any

potential interferences on the OSHA-91A form.

Submit the samples

to the OSHA Salt Lake Technical Center together with OSHA-91A forms as

soon as possible after sampling. Ship any bulk samples separate from the

surface samples. Package, label, and ship samples according to

current DOT regulations.

2.5 Extraction efficiency (Section

4.4)

It is the responsibility of each analytical laboratory to

determine the surface sample extraction efficiency because the wipe

sampling media, reagents and laboratory techniques may be different than

the those listed in this evaluation and influence the results.

2.5.1 The mean extraction efficiency for 1,6-hexamethylene

diisocyanate from Ghost Wipes over the range of RQL to 10 times the

target concentration (0.99 to 3400 µg per sample) was

96.8%.

2.5.2 Extracted samples

remain stable for at least 24 h.2.6 Interferences,

sampling

Suspected interferences should be reported to the

laboratory with submitted samples.

Blank wipe sampling media was

moistened with the wetting reagent, placed in vials and analyzed.

Additional samples were prepared by wiping glass plates with wipe

sampling media moistened with the wetting reagent. The surfaces were not

spiked with HDI. The samples were analyzed. No significant interferences

were found. (Section 4.6)3.

Analytical Procedure

Adhere to the rules set down in your Chemical

Hygiene Plan14.

Avoid skin contact and inhalation of all chemicals and review all

appropriate MSDSs before beginning the analytical procedure.

This

analysis closely follows the analytical procedure in OSHA Method

42.15

3.1 Apparatus

3.1.1 A high performance liquid chromatograph (HPLC)

equipped with fluorescence (FL) and ultraviolet (UV) detectors,

liquid chromatograph pump, manual or automatic injector, and chart

recorder. A Hewlett-Packard Series 1050 HPLC equipped with a UV

detctor and a Kratos Spectroflow 980 FL detector was used in this

evaluation.

3.1.2 LC column capable of separating diisocyanate

derivatives. A 25-cm × 4.6-mm i.d. Alltech Econosphere CN (5-µm)

column was used during this evaluation.

3.1.3 An

electronic integrator, or some other suitable method of measuring

detector response. A Waters Corporation Millennium32

(version 3.20) data system was used in this evaluation.

3.1.4

Vials, 2-mL with PTFE-lined caps.

3.1.5 Volumetric flasks,

pipets, and syringes.

3.1.6 Micro-analytical balance used to

weigh standard preparations.

3.1.7 Centrifuge. 3.2

Reagents

3.2.1 Acetonitrile (ACN), HPLC grade, Lot No. 012683,

Fisher Scientific, Fair Lawn, NJ.

3.2.2 Water, HPLC grade. A

Millipore Milli-Q system was used to prepare the water for this

evaluation.

3.2.3 Ethyl acetate, HPLC grade, Lot No. 924366,

Fisher Scientific, Fair Lawn, NJ.

3.2.4 Dimethyl

sulfoxide (DMSO), HPLC grade, Lot No. BB965, Baxter, Muskegon,

MI.

3.2.5 1,6-Hexamethyl diisocyanate (HDI), Lot No.

01104EU, Aldrich, Milwaukee, WI.

3.2.6 1-(2-pyridyl) piperazine

(1-2PP), Lot No. 09914JU, Aldrich, Milwaukee, WI.

3.2.7

Ammonium acetate, Lot No. 897484, Fisher Scientific, Fair Lawn,

NJ.

3.2.8 Phosphoric acid, Lot No. 025821, Baker, Phillipsburg,

NJ.

3.2.9

N,N'-1,6-hexanediylbis[4-(2-pyridinyl)-1-piperazinecarboxyamide],

(1-(2-pyridyl)piperazine derivative of HDI), U. S. Department of Labor

OSHA Technical Center Salt Lake City, UT. (An external source

is: Product number 48146, Supelco, Bellefonte, PA.) 3.3

Standard preparation

3.3.1 All applicable Quality Assurance procedures and

accreditation requirements should be observed.

3.3.2 A stock

standard solution is prepared by dissolving derivatized HDI in DMSO.

The derivatized HDI may be purchased or prepared following Section

3.3.1 of OSHA Method 4216.

The ratio of the molecular weights of HDI to the HDI derivative is

0.340. Use this factor to express the mass of HDI derivative as the

mass of HDI. All dilutions of the stock solutions are made with 90:10

ACN:DMSO to arrive at the working range.

3.3.3 Bracket sample

concentrations with standard concentrations. If, upon analysis,

sample concentrations fall outside the range of prepared

standards, prepare and analyze additional standards to confirm

instrument response, or dilute high samples with the 90:10 ACN:DMSO

dilution solution. 3.4 Sample preparation

3.4.1 The surface samples are received in 20-mL vials

containing the wipe media and 5.0 mL of derivatizing reagent solution.

The vials are placed in a centrifuge that has been set at 2500 rpm for

4 min.

3.4.2 Remove an aliquot of approximately 1 mL and place

into an appropriate autosampler vial and seal with a PTFE-lined cap.

3.5 Analysis

3.5.1 HPLC conditions

| column: |

25-cm × 4.6-mm i.d. Alltech

Econosphere CN (5 µm). |

|

| mobile phase: |

40:60 ACN:water, 0.02 M ammonium

acetate adjusted to pH 5.9 with phosphoric acid. |

| flow rate: |

1.0 mL/min for 15 min |

| FL detector: |

240 nm excitation, 370 nm

emission |

| UV detector: |

254 nm |

| injection size: |

10 µL |

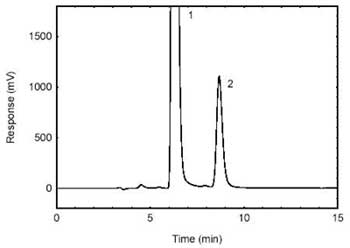

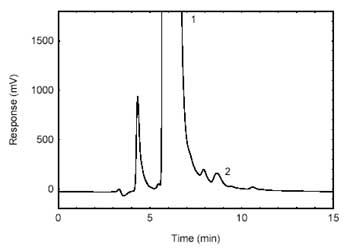

Figure 3.5.1.

Chromatogram obtained from the samples spiked at the target

concentration and diluted 1/50. (1- excess 1-2PP (derivatizing

reagent); 2-HDI. |

| retention time: |

9 min |

| chromatogram: |

Figure

3.5.1 |

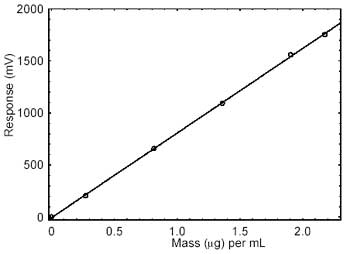

|

| Figure 3.5.2. Calibration curve

of HDI. (Y=813X - 6.30) |

3.5.2 An external standard (ESTD) calibration procedure

is used to prepare a calibration curve using at least 2 stock

standards from which dilutions are made. The calibration curve is

prepared daily. The samples are bracketed with analytical

standards.

3.6 Interferences

(analytical)

3.6.1 Any compound that produces a fluorescence or UV

detector response and has a similar retention time as HDI is a

potential interference. If any potential interferences were reported,

they should be considered before samples are extracted. Generally,

chromatographic conditions can be altered to separate an interference

from the analyte. Material Safety Data Sheets (MSDS) identify solvents

prevalent in spray painting operations. Three solvents commonly found

were separately added to individual media that had been placed in

vials, moistened with the wetting reagent and spiked with HDI at the

target level. The samples were prepared and analyzed. Benzaldehyde and

2,4-toluene diisocyanate were also tested as potential interferences

in the same manner. Neither the solvents or the chemicals caused a

discernable interference. (Section 4.6)

3.6.2 When necessary,

the identity of an analyte peak may be confirmed with additional

analytical data. An absorbance response ratio of UV detector response

to fluorescence detector response is determined. The response ratio of

samples and standards of similar concentration are compared. (Section

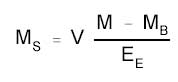

4.8) 3.7 Calculations

The amount of HDI per sampler

is obtained from the appropriate calibration curve in terms of

micrograms per mL, uncorrected for extraction efficiency. This amount is

then adjusted by subtracting the amount (if any) found on the blank and

corrected for extraction efficiency. Correct for the 5.0 mL of

derivatizing solution that was present in the samples when they were

received and any dilutions performed. Perform the calculation using the

following formula.

|

where |

MS is the mass

of HDI recovered from the sampled surface (µg) |

|

V is the volume of the derivatizing

solution and any dilutions (mL) |

|

M is micrograms per mL from the

sample derivatizing solution |

|

MB is micrograms per mL

from the blank derivatizing solution |

|

EE is the extraction

efficiency |

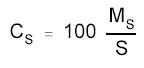

The amount

may be expressed as micrograms HDI per 100 cm2 if the surface

area that was sampled was provided, by using the following

formula.

|

where |

MS is the mass

on the sampled surface (µg) |

|

CS is the mass (in µg) of

HDI per 100 cm2 |

|

S is the surface area sampled

(cm2) |

|

100 is 100

cm2 |

The

surface that was sampled may be less ideal (more porous, less smooth)

than the surface that was used to evaluate the removal efficiency of the

sampling media. In this circumstance, the media will remove the surface

contaminant less effectively. There may be significant amounts of

contaminant remaining on the surface after sampling. Nevertheless, the

amount found in the sample indicates that at least this amount of HDI

was present on the surface.4.

Backup Data

General background information about the determination

of detection limits and reproducibility of the overall procedure is found

in the "Evaluation Guidelines for Surface Sampling Methods".17

4.1 Detection limit of the overall procedure (DLOP) and

reliable quantitation limit (RQL)

Table

4.1

Detection Limit of the Overall Procedure |

|

mass per

sample

(µg) |

response

(mV) |

|

| 0 |

35 |

| 0.66 |

102 |

| 1.32 |

193 |

| 1.98 |

304 |

| 2.64 |

400 |

| 3.30 |

506 |

| The DLOP is measured as

mass per sample. Five samplers were moistened with 0.5 mL wetting

solution and spiked with equal descending increments of analyte, such

that the highest sampler loading was 3.30 g/sample. 5.0 mL of

derivatizing reagent was added to these spiked samplers, and also a

sample blank. The samplers were analyzed with the recommended analytical

parameters, and the data obtained used to calculate the required

parameters (standard error of estimate and the slope) for the

calculation of the DLOP. The data is presented in Table 4.1.

Values of 145.5 and 14.0 were obtained for the slope and standard error

of estimate, respectively. The DLOP was calculated to be 0.29

µg/sample.

The RQL is considered the lower limit for precise

quantitative measurements. It is determined from the regression line

parameters obtained for the calculation of the DLOP, providing 75% to

125% of the analyte is recovered. The RQL is 0.962 µg/sample. Average

recovery at this level is 90.5%.

|

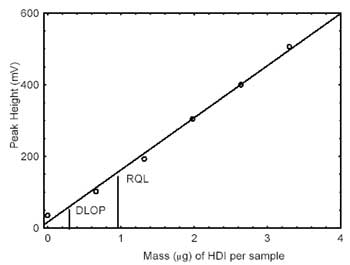

|

| Figure 4.1.1. Plot of data to

determine the DLOP/RQL. (Y=146X + 16.7) |

Figure 4.1.2. Chromatogram of the

RQL. (1)- derivatizing reagent; (2)

-HDI. |

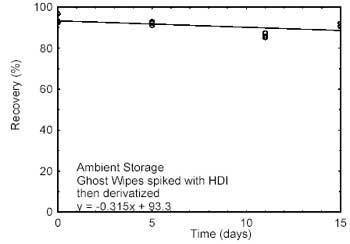

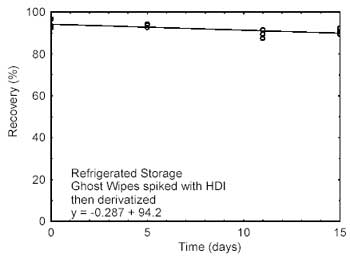

4.2 Storage

tests

Storage samples were prepared by spiking Ghost Wipes, that

had been moistened with the wetting solution, with HDI at the target

concentration. Samples were immediately placed in vials containing the

derivatizing reagent. Twenty-one storage samples were prepared. Three

samples were analyzed on the day prepared. Nine of the samples were

stored at reduced temperature (4 °C) and the other nine were stored in a

closed drawer at ambient temperature (about 22 °C). At about 5-day

intervals, three samples were selected from each of the two storage sets

and analyzed. Sample results were not corrected for extraction

efficiency.

Table

4.2

Storage Test for HDI |

|

time

(days) |

ambient

storage

recovery (%) |

refrigerated

storage

recovery (%) |

|

| 0 |

93.1 |

69.7 |

92.4 |

93.1 |

96.7 |

92.4 |

| 5 |

92.3 |

91.1 |

92.9 |

94.3 |

92.7 |

93.9 |

| 11 |

85.1 |

85.9 |

87.4 |

87.4 |

91.5 |

89.4 |

| 15 |

90.6 |

90.9 |

90.7 |

90.7 |

92.3 |

89.4 |

|

|

|

| Figure 4.2.1. Ambient storage test

for HDI. |

Figure 4.2.2. Refrigerated Storage

test for HDI. |

4.3

Sampler removal efficiency

Table

4.3

Sampler Removal Efficiency

Data for HDI on Ghost

Wipes |

|

theoretical

(µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

| 340 |

220 |

64.7 |

| 340 |

246 |

72.3 |

| 340 |

244 |

71.7 |

| 340 |

219 |

64.4 |

| 340 |

228 |

67.1 |

| 340 |

236 |

69.3 |

|

Six glass surfaces

were spiked at the target concentration of HDI, 340 µg /100

cm2. Samples were collected from each surface using the

technique described in Section 2.4 and analyzed. Sample results were

corrected for extraction efficiency. The results are shown in Table

4.3.

4.4 Extraction efficiency and stability of extracted

samples

The extraction efficiency is dependent on the solvents

used in the derivatizing solution.

4.4.1 Extraction efficiency

The extraction

efficiencies of HDI were determined by liquid-spiking Ghost Wipes with

the HDI at concentrations ranging from the RQL to 10 times the target

concentration. The sample media was placed in vials and moistened with

the wetting solution. Each sampler was then spiked and the

derivatizing reagent solution was added. Four samplers at each

concentration were prepared. The samples were placed on a rotator for

an hour. These samples were stored overnight at ambient temperature

and then analyzed. The mean extraction efficiency over the working

range of the RQL to 10 times the target concentration is 96.8%. Note

that extraction efficiency also accounts for the additional volume of

the wetting reagent.

Table

4.4.1

Extraction Efficiency of HDI from Ghost Wipe |

|

| level |

sample

number |

× target

concn |

µg per

sample |

1 |

2 |

3 |

4 |

mean |

|

| RQL |

0.99 |

90.2 |

88.2 |

92.0 |

91.5 |

90.5 |

| 0.1 |

34.0 |

100.1 |

100.9 |

98.8 |

94.8 |

98.7 |

| 1.0 |

340 |

98.6 |

98.7 |

97.9 |

97.5 |

98.1 |

| 10.0 |

3400 |

99.2 |

100.9 |

100.1 |

99.2 |

99.9 |

|

4.4.2 Stability of

extracted samples

The stability of extracted samples was

investigated by re-analyzing the four target concentration samples 24

h after initial analysis. After the original analysis, two of the

auto-

sampler vials were recapped with new septa, while the

remaining two retained their punctured septa. The samples were

re-analyzed with fresh standards. The average percent change was 1.1%

for the samples that were resealed and 1.2% for those that were stored

with their septa punctured. The septum was punctured 3 times for each

injection.

Table

4.4.2

Stability of Extracted Samples for HDI |

|

| punctured

septa replaced |

punctured

septa retained |

initial

(%) |

after

one

day

(%) |

difference

(%) |

initial

(%) |

after

one

day

(%) |

difference

(%) |

|

| 98.6 |

100.4 |

1.8 |

97.9 |

98.7 |

0.8 |

| 98.7 |

98.3 |

0.4 |

97.5 |

99.1 |

1.6 |

|

4.5

Reproducibility

4.5.1 Six glass surfaces were spiked at the target level

of 340 µg. Two chemists, other than the one developing the method,

conducted sampling on the glass surfaces as described in Section

2. The test was repeated with a second chemist performing the

sampling. Sample results were corrected for extraction

efficiency.

Table

4.5.1.1

Sampling Reproducibility

Data for HDI on Ghost

Wipe,

1st Chemist |

|

Table

4.5.1.2

Sampling Reproducibility

Data for HDI on Ghost

Wipe,

2nd Chemist |

|

|

|

theoretical

(µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

theoretical

(µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

|

|

| 340 |

176 |

51.9 |

|

340 |

200 |

58.8 |

| 340 |

212 |

62.3 |

|

340 |

176 |

51.7 |

| 340 |

209 |

61.4 |

|

340 |

212 |

62.4 |

| 340 |

208 |

61.2 |

|

340 |

177 |

52.0 |

| 340 |

222 |

65.4 |

|

340 |

176 |

517 |

| 340 |

212 |

62.2 |

|

340 |

191 |

56.1 |

|

|

|

Table

4.5.2

Analytical Reproducibility

Data for HDI on Ghost

Wipes |

|

theoretical

(µg/surface) |

recovered

(µg/sample) |

recovery

(%) |

|

| 340 |

382 |

112 |

| 340 |

370 |

109 |

| 340 |

375 |

110 |

| 340 |

365 |

107 |

| 340 |

393 |

116 |

| 340 |

377 |

111 |

|

4.5.2 Six samples were prepared by spiking media in the

same manner that was used in the preparation of samples for the

storage study. The samples were submitted to the OSHA SLTC for

analysis. The samples were analyzed after being stored for 22

days at 22 °C. Sample results were corrected for extraction

efficiency.

4.6 Interferences

4.6.1 Media

Tests were conducted to determine

interference due to contamination of the prepared media. Two

blank wipe sampling media were placed in vials, moistened with the

recommended solvent. The derivatizing reagent solution was added and

the samples were processed and analyzed.

Table

4.6.1

Interference to the Analysis of HDI

from the Media

or Surface (µg found) |

|

| sample |

1 |

2 |

mean |

|

| blank |

0.00 |

0.29 |

0.14 |

| from surface |

0.00 |

0.00 |

0.00 |

| Two additional samples

were prepared by wiping the same type of surface that was used for the

removal efficiency test (glass plate) with media moistened with 50:50

isopropanol:DI water. The surfaces were not spiked with HDI. The

samples were placed in vials containing the derivatizing reagent

solution, processed and analyzed. The results are shown in Table

4.6.1.

4.6.2 Tests were conducted to determine the

effects of potential interference from three solvents that are

commonly found in auto-body repair shops (toluene, 2-heptanone and

petroleum distillate) and also, two additional chemicals (benzaldehyde

and 2,4-toluene diisocyanate). Three samplers were prepared for

each compound tested. The sample media was placed in vials and

moistened with 0.5 mL of the wetting solution. Each sampler was then

spiked with 340 µg HDI and 5.0 mL of the derivatizing reagent. A

potential interfering compound was then added. The samples were

processed and analyzed. The amounts of interfering compound added and

the results are shown in Table 4.6.2. None of the compounds tested

caused a significant interference.

Table

4.6.2

Interference to the Analysis of HDI, with an

interferant compound added.

(µg found, not corrected for

extraction efficiency) |

|

| potential

interferant |

amount

of

interferant

spiked (µg) |

amount of

HDI spiked (µg) |

amount of

HDI recovered |

| 1 |

2 |

3 |

mean |

|

| toluene |

173400 |

340 |

319 |

320 |

315 |

318 |

| 2-heptanone |

164000 |

340 |

305 |

307 |

305 |

306 |

| petroleum

distillate |

145300 |

340 |

309 |

307 |

311 |

309 |

| benzaldehyde |

650 |

340 |

297 |

318 |

313 |

309 |

| 2,4-TDI |

650 |

340 |

312 |

320 |

318 |

317 |

| 4.7 Analyte

confirmation or qualitative analysis

Diisocyanate qualitative

analysis confirmation is not performed by GC/MS because the derivatized

diisocyanate is not sufficiently volatile for gas chromatography.

Diisocyanate may be confirmed by a peak ratio technique. The analysis is

conducted with fluorescence and UV detectors in series. A ratio is

established between fluorescence detector response and UV detector

response of a standard that is the approximate concentration of the

sample. A similar ratio is established between fluorescence detector

response and UV detector response of the sample. The ratio of the sample

is compared to the ratio of the standard for diisocyanate confirmation.

Any required laboratory confirmation criteria must be met before the

analyte confirmation is reported.

4.8 Derivatizing reagent

storage test

Table

4.8

Derivatizing Reagent Storage Test (60 days) |

|

×

target

concn |

ambient

storage

recovery (%) |

refrigerated

storage

recovery (%) |

|

| 0.1 |

93.4 |

88.4 |

| 1.0 |

96.4 |

97.4 |

| 10.0 |

99.2 |

99.6 |

| Derivatizing reagent

solution was prepared as in Section 2.3 and divided into two portions.

One portion was placed in a refrigerator. The other portion was placed

in a fire cabinet at ambient temperature. After sixty days fresh

derivatizing reagent was also prepared. Standards were prepared at 0.1,

1.0, and 10 times the target concentration using fresh derivatizing

reagent. Spiked samples were prepared at 0.1, 1.0, and 10 times the

target concentration using the ambient and refrigerated derivatizing

reagent solutions. Excess derivatizing reagent peak was noted on the

chromatograms for all samples and standards. Samples prepared with the

derivatizing reagent solution that was stored at ambient temperatures

for sixty days gave average results that were 93.4%, 96.4%, 99.2% of the

0.1, 1.0, and 10 times the target concentration, respectively. Samples

prepared with the derivatizing reagent solution that was stored at

refrigerated temperatures for sixty days gave average results that were

88.4%, 97.4%, 99.6% of the 0.1, 1.0, and 10 times the target

concentration, respectively. The results are shown in Table 4.8. The

effect of light on the derivatizing solution was not tested. The

derivatizing reagent solution may be stored in a dark place with

adequate ventilation, at room temperature for at least two months. No

refrigeration is required for storage.

|

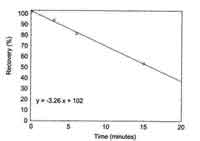

| Figure 4.9. Average recovery of HDI

at timed reaction intervals with wetting

solution. | 4.9

Reaction time study

Many texts

and articles indicate that water and alcohols will react with

isocyanates. One published study determined that the reaction rate of

water with isocyanates was at least 5 orders of magnitude (100,000)

times slower than the reaction rate of the derivatizing reagent,

1,2-pyridyl piperazine with isocyanates.18

The use of a wetting solution consisting of 50:50 isopropanol:water in

this method required a reaction rate test to be performed. The test was

to determine whether the water and isopropanol in the wetting reagent

reacts with HDI rapidly enough to be a concern, relative to the amount

of time it takes to collect a sample and deposit it into a vial

containing the derivatizing reagent. Vials containing 0.5 mL 50:50

isopropanol:water (wetting solution) were spiked with HDI at 1.0, 0.5

and 0.1 times the target concentration. Two vial at each concentration

were prepared. Five milliliters of derivatizing reagent was added as

quickly as possible. The vials were capped and agitated to insure

mixing. The procedure was repeated three more times, except intervals of

3, 6 and 15 minutes were allowed to pass before adding the derivatizing

reagent. Standards bracketing the concentrations were prepared with the

same spiking solution in a similar manner, with no wetting solution, but

in 5.5 mL of derivatizing reagent. Analysis was conducted and the result

are presented in Table 4.9. The concentration of the spike did not

appear to effect the recovery but the amount of time the spike was

allowed to remain in the wetting reagent before being derivatized did

effect the recovery. The percent recovery for all concentrations was

averaged for each reaction time interval and plotted against time in

minutes (Figure 4.9). Using the equation of the line, the recovery can

be predicted for a given reaction time. The average recovery at 3.5

minutes is 90.6%. Based on this information, the amount of time it takes

to collect a sample is important. The time interval, from beginning to

collect the sample, until the sample is placed in the vial containing

the derivatizing reagent, should not exceed three minutes.

Table

4.9

Percent Recovery of HDI After Timed Reaction Intervals With

the

Wetting Solution |

|

| µg spiked |

"Immediate" |

3 minutes |

6 minutes |

15 minutes |

|

| 34.0 |

105.4 |

97.7 |

89.0 |

62.5 |

| 34.0 |

105.6 |

100.3 |

87.2 |

59.2 |

| 170.0 |

99.7 |

92.2 |

78.3 |

49.8 |

| 170.0 |

97.9 |

88.9 |

77.3 |

50.4 |

| 340.0 |

101.6 |

92.5 |

79.5 |

50.4 |

| 340.0 |

101.7 |

92.4 |

77.9 |

49.5 |

| Average |

101.9 |

94.0 |

81.5 |

53.7 |

|

References:

1.

Diisocyanates, 1,6-Hexamethylene Diisocyanate (HDI),

Tolune-2,6-Diisocyanate, Tolune-2,4-Diisocyanate, Method 42, 1989; org042/org042.html,

(accessed May 2000).

2. Toxicological Profile for Hexamethylene Diisocyanate,

U.S. Department of Health and Human Services, Public Health Service,

Agency for Toxic Substances and Disease Registry, Atlanta, GA, 1998, pp

59-67.

3. Rattray, N., et al. Induction of

Respiratory Hypersensitivity to Diphenylmethane-4-4' diisocyanate (MDI) in

Guinea Pigs. Influence of Route Exposure. Toxicology 1994, 88, pp 15-30.

4. Karol, M. H., et

al. Dermal Contact with Tolune Diisocyanate (TDI) Procedures Respiratory

Tract Hypersensitivity in Guinea Pigs, Toxicology and

Applied Pharmacology 1981, 58, pp 221-230.

5. Kimber, I. The

Role of the Skin in the Development of Chemical Respiratory

Hypersensitivity, Toxicology Letters 1996, 86, pp 89-92.

6. Bickis, U. Investigation of Dermally Induced Airway

Hyperreactivity to Tolune Diisocyanates in Guinea Pigs. Ph.D. thesis,

Queen's University, Kingston, Canada, 1994.

7. Criteria for a Recommended Standard... Occupational Exposure

to Diisocyanate; DHEW (NIOSH) Publ. No. 78-215; U.S. Department if

Health, Education and Welfare, Public Health Service, Center for Disease

Control, National Institute for Occupational Safety and Health, U.S.

Government Printing Office: Washington DC, 1978, pp 35-36.

8. Maitre A., et al. Urinary Hexane Diamine as an Indicator of

Occupational Exposure to Hexamethylene Diisocyanate, International Archives of Occupational and Environmental

Health 1996, 69,

pp 65-68.

9. National Occupational Exposure Survey;

U.S. Department of Health, Education and Welfare, Public Health Service,

Center for Disease Control, National Institute for Occupational Safety and

Health, Cincinnati, OH, 1989.

10. Toxicological Profile for Hexamethylene Diisocyanate,

U.S. Department of Health and Human Services, Public Health Service,

Agency for Toxic Substances and Disease Registry, Atlanta, GA, 1998, pp

100-102.

11. Chemical Sampling Information,

Hexamethylene Diisocyanate, http://www.osha-slc.gov/dts/chemicalsampling/data/CH_245198.html,

(accessed May 2001).

12. RTECS 2000,

1,6-Diisocyanate Hexane, Registry of Toxic Effects of Chemical Substances,

U.S. Department of Health and Human Services, National Institute for

Occupational Safety and Health, Washington, DC, December 2000.

13. Lawrence, R. Evaluation Guidelines for

Surface Sampling Methods; OSHA Salt Lake Technical Center, U.S.

Department of Labor: Salt Lake City , UT, 2001 (unpublished).

14. Occupational Exposure to Chemicals in Laboratories. Code

of Federal Regulations, Part 1910.1450, Title 29, 1998;

http://www.osha.gov/OshaStd_data/1910_1450_APP_A.html, (accessed May

2000)

15. Diisocyanates, 1,6-Hexamethylene

Diisocyanate (HDI), Toluene-2.6-Diisocyanate, Toluene-2.4-Diisocyanate,

Method 42, 1989; org042/org042.html,

(accessed May 2000).

16. Diisocyanates,

1,6-Hexamethylene Diisocyanate (HDI), Toluene-2.6-Diisocyanate,

Toluene-2.4-Diisocyanate, Method 42, 1989; org042/org042.html,

(accessed May 2000).

17. Lawrence, R. Evaluation Guidelines for Surface Sampling Methods;

OSHA Salt Lake Technical Center, U.S. Department of Labor: Salt Lake City

, UT, 2000, unpublished.

18. Wu, W., et al.

Application of Tryptamine as a Derivatizing Agent for Airborne Isocyanate

Determination part 4. Evaluation of Major High-performance Liquid

Chromatographic Methods Regarding Airborne Isocyanate Determination With

Specific Investigation of the Competitive Rate of Derivatization, Analyst 1991, 119, p

24.

|