|

| Method no.: |

ID-182 (This method supersedes

ID-109) |

| |

|

| Matrix: |

Air |

| |

|

OSHA Permissible Exposure

Limits

Final Rule Limit:

Transitional Limit: |

1 ppm Short-Term

Exposure Limit (STEL)

5 ppm Ceiling |

| |

|

| Collection Device: |

Each sample is collected using a

sampling tube containing triethanolamine-impregnated

molecular sieve (TEA-IMS) and a calibrated sampling

pump. |

| |

|

| Recommended Sampling Rate: |

I0.20 L/min |

| |

|

| Recommended Air Volume: |

3.0 L (0.20 L/min for 15 min) |

| |

|

| Analytical Procedure: |

The sample is desorbed from the solid

sorbent using a 1.5% triethanolamine (TEA) solution. Analysis is

performed as nitrite (NO2-) by ion

chromatography. |

| |

|

Detection Limit

Qualitative:

Quantitative: |

0.07 ppm (3-L air

sample)

0.19 ppm (3-L air

sample) |

| |

|

Precision and Accuracy

Validation Range:

CVT:

Bias

Overall Error: |

2.64 to 9.45 ppm

0.034

+0.13

±19.8% |

| |

|

| Method Classification: |

Validated Method |

| |

|

| Chemist: |

James Ku |

| |

|

| Date (Date Revised): |

December 1987 (May, 1991) |

| |

|

Commercial manufacturers and products mentioned in this method are

for descriptive use only and do not constitute endorsements by

USDOL-OSHA.

Similar products from other sources can

be substituted.

|

| |

|

Branch of Inorganic Methods Development

OSHA Technical

Center

Sandy City, Utah

|

1.

Introduction

This method

describes the collection and analysis of airborne nitrogen dioxide

(NO2). Samples are taken in the breathing zone of

workplace personnel and analysis is performed by ion chromatography

(IC).

1.1. History

Previous methods of analysis for

NO2 involved collection of nitrogen dioxide in bubblers

of triethanolamine (TEA) solution or a

triethanolamine-impregnated molecular sieve

(TEA-IMS) solid sorbent and TEA extraction (8.1.).

Nitrogen dioxide exposure was determined colorimetrically by the

Griess-Saltzman reaction (8.1.-8.3.).

This method, like most colorimetric procedures, can have

significant interferences. A differential pulse polarographic

(DPP) method (8.4.)

was later developed to improve sensitivity and decrease the

potential for interferences. The sensitivity of the DPP method was

adequate for measuring workplace concentrations of nitrogen

dioxide; however, the nitrite ion is unstable at the pH range (pH

1-2) used during analysis (8.5.).

Method no. ID-182 uses the collection

principle of the TEA-IMS tube. The samples are

analyzed by IC to determine NO2 exposure.

1.2.

Principle

A known volume of air is drawn through a

sampling tube containing TEA-IMS. Nitrogen dioxide is

trapped and converted to nitrite in the presence of TEA and water.

Samples are desorbed using an aqueous TEA solution and analyzed as

nitrite. The conversion mechanism of NO2 gas to nitrite

ion has been proposed by Gold (8.6.).

The following is Gold's proposal for the reaction of equivalent

amounts of NO2 and TEA in an aqueous solution:

2NO2

< = > N2O4

N2O4 +

(HOCH2CH2)3N

-->

(HOCH2CH2)3NNO+NO3-

(HOCH2CH2)3NNO+NO3-

+ H2O -->

(HOCH2CH2)3NH+NO3-

+ HNO2

HNO2 --> H+

+ NO2-

|

Nitrogen

dioxide disproportionates to nitrite and nitrate ions in the

presence of TEA. The nitrite ion (NO2-)

formed from the above reaction can be analyzed via conventional

analytical methods (8.1.-8.5.)

including IC (8.7.).

The high background levels of nitrate found in commercial

TEA-IMS sorbents ruled out further research to assess

this NO2-TEA disproportionation product by

IC.

This reaction path requires a stoichiometric factor of

0.5 for the conversion of gaseous NO2 to

NO2-. Experiments indicate the proposed

factor of 0.5 is seen only when NO2 concentrations are

greater than 10 ppm (8.6.,

8.8.-8.9.).

The conversion factor has been experimentally determined to

average approximately 0.6 to 0.7 when concentrations are below 10

ppm (8.1.-8.4.,

8.6.-8.9.).

The deviation from ideal stoichiometry is believed to be due to

other competing reactions; however, evidence to support this has

not been found (8.6.).

1.3. Advantages and Disadvantages

1.3.1. The analysis is simple, rapid, easily

automated, and specific for the nitrite ion.

1.3.2.

After sample preparation, nitrogen dioxide (as nitrite ion) can

also be determined by polarographic or colorimetric analytical

techniques (8.1.-8.4.).

1.3.3. Nitric oxide (NO) can also be sampled when using

a three-tube sampling device (8.10.).

Sulfur dioxide may also be screened using the

TEA-IMS sampling tube and similar analytical

conditions (8.7.).

1.3.4. A disadvantage is the potential interference from

large amounts of soluble chloride salts present in commercial

molecular sieve. Prior to TEA impregnation, the molecular sieve

should be washed with deionized water to remove any soluble

chloride salts.

1.3.5. Another disadvantage is the need

for a concentration-dependent conversion factor

when calculating results. 1.4. Physical Properties (8.11.)

Nitrogen dioxide (CAS No. 10102-44-0), one of

several oxides of nitrogen, is a reddish-brown or dark orange gas

with a formula weight of 46.01. Its dimer, nitrogen tetroxide

(N2O4), is colorless. At temperatures

between -9.3 and 135 °C, NO2 and

N2O4 coexist as a mixture of gases. Below

-9.3 °C, a colorless solid consisting of

N2O4 is formed, while above 135 °C, the gas

is mainly composed of NO2. Physical characteristics of

NO2 are:

| Formula weight |

46.01 |

| Specific gravity |

1.448 at 20 °C (liquid) |

| Melting point |

-9.3 °C |

| Boiling point |

21.15 °C |

| Vapor pressure |

96 KPa (720 mmHg) at 20 °C |

| Vapor density |

1.58 (air = 1) |

| Other characteristics |

strong oxidizer, corrosive,

nonflammable |

| Synonyms |

dinitrogen tetroxide, nitrogen tetroxide,

nitrogen peroxide, liquid

dioxide |

1.5.

Some sources for potential nitrogen dioxide exposures are:

agricultural silos

arc or gas welding (esp.

confined space operations)

electroplating plants

food and

textile bleaching

jewelry manufacturing

nitric acid

production

nitrogen fertilizer production

nitro-explosive

production

pickling plants Nitrogen dioxide and nitric oxide usually exist

together in industrial settings. Nitric oxide is reactive in air

and produces NO2 according to the following equations

(8.11.):

2NO

+ O2 --->

2NO2

d(NO2) / dt =

K(O2)(NO)2

|

(K is a

temperature dependent constant. At 20 °C, K = 14.8 ×

109)

An experimental approximation of the NO /

NO2 distribution found in various industrial operations

is shown (8.11.).

Source

|

% NO2

|

% NO

|

| Carbon arc |

9 |

91 |

| Oxyacetylene torch |

8 |

92 |

| Cellulose nitrate combustion |

19 |

81 |

| Diesel exhaust |

35 |

65 |

| Dynamite blast |

52 |

48 |

| Acid dipping |

78 |

22 |

The potential for exposure to both NO2

and NO should be considered because NO is easily oxidized to

NO2 and both oxides are likely to coexist in industrial

settings.

1.6. Toxicology

Information listed within this section is a synopsis of

current knowledge of the physiological effects of nitrogen dioxide

and is not intended to be used as a basis for OSHA policy.

1.6.1. Nitrogen dioxide is classified as a

respiratory irritant and the route of exposure is mainly

inhalation. The term silo-fillers' disease is

associated with exposure to nitrogen dioxide as well as other

nitrogen oxides.

Unlike the more soluble gases (e.g.

chlorine, ammonia) that produce almost immediate upper

respiratory tract irritation, symptoms of NO2

exposure may be delayed for up to 12 hours. The lower solubility

of NO2 provides less warning and increases the

potential for physiological damage when exposures occur.

1.6.2. The symptoms from mild exposures (<50 ppm) are

generalized below (8.12.-

8.14.):

| mucoid or frothy sputum production |

cough |

| painful breathing |

fever |

| chest pains |

tachycardia |

| increased breathing rate |

lymphocytosis |

Exposures usually result in an increased

susceptibility to respiratory infections. Changes in pulmonary

function are evident when healthy subjects are exposed to 2 to 3

ppm NO2 and can occur at far lower concentrations in

asthmatic subjects.

More severe exposures (>50 ppm)

are characterized by pulmonary edema, cyanosis, bronchiolitis

obliterans, respiratory failure and death.

1.6.3. The

LC50 (Lethal Concentration 50) for a

4-hour exposure is approximately 90 ppm

NO2. 2. Range, Detection Limit and

Sensitivity (8.8.)

2.1. This method was evaluated over the concentration

range of 2.64 to 9.45 ppm. An air volume of 3 L and a flow rate of

0.2 L/min were used. Samples were taken for 15 min. Sample results

were calculated using an average conversion relationship of:

At NO2 concentrations above 10 ppm, the

conversion factor has been shown to decrease, approaching a value

of 0.5 (8.6.,

8.8.-

8.9.).

2.2. The qualitative detection limit was 0.08 µg/mL or

0.24 µg (as NO2-) when using a

3-mL solution volume. This corresponds to 0.07 ppm

NO2 for a 3-L air volume.

2.3. The

quantitative detection limit was 0.23 µg/mL or 0.69 µg (as

NO2-) when using a 3-mL

solution volume. This corresponds to 0.19 ppm NO2 for a

3-L air volume. A 50-L sample loop and a

detector setting of 3 microsiemens were used for both detection

limit determinations.

2.4. The sensitivity of the

analytical method was calculated from the slope of a linear

working range curve (1 to 20 µg/mL nitrite). The sensitivity for

this curve was 222,720 area units per 1 µg/mL (a

Hewlett-Packard 3357 data reduction system was used,

and 1 area unit = 0.25 microvolt-second).

3. Method

Performance (8.8.)

3.1. The pooled coefficient of variation

(CVT) for samples taken in the range of 2.64 to 9.45

ppm was 0.034. The method exhibited positive bias (+0.13);

however, overall error is within acceptable limits at ±19.8%.

3.2. The collection efficiency at approximately 2 times

the PEL was 97.3%. Samples were collected at a generation

concentration of 9.45 ppm NO2 for 15 min. Sample

generation conditions were 50% RH and 25 °C.

3.3.

Breakthrough tests were performed at 30% RH and a concentration of

21 ppm. Samples were collected for 15 min at a flow rate of 0.18

L/min. Breakthrough of NO2 into a second sorbent tube

at these parameters was 1.6% NO2. This is within an

acceptable limit of <5% breakthrough.

3.4. Samples can

be stored at ambient (20 to 25 °C) laboratory conditions for a

period of at least 29 days. Storage stability results show the

mean of samples analyzed after 29 days was within ±5% of the mean

of samples analyzed after one day of storage. Samples were stored

on a laboratory bench. 4. Interferences

4.1. When other compounds are known or suspected to be

present in the sampled air, such information should be transmitted

to the laboratory with the sample.

4.2. Any compound

having the same retention time as nitrite, when using the

operating conditions described, is an interference.

4.3

Interferences may be minimized by changing the eluent

concentration, and/or pump flow rate.

4.4. If there is

reason to suspect an unresolvable interference, alternate

polarographic or colorimetric methods can be used (8.1.-8.4.).

4.5. Contaminant anions normally found in molecular sieve,

such as NO3-,

SO42-, and

PO43-, do not interfere. Large

amounts (greater than 4 to 5 µg/mL) of Cl- can

interfere. 5.

Sampling

5.1. Equipment

5.1.1. Personal sampling pumps

capable of sampling within ±5% of the recommended flow rate of

0.2 L/min are used.

5.1.2. Two types

of sampling tubes are commercially available (All molecular sieve used for tube packing

should be washed with deionized water before impregnation with

TEA):

- One type is a two-section tube packed with a

400-mg TEA-IMS front and a 200-mg

back-up section (NO2 sampling tube,

Cat. No. 226-40-02-special order, water-washed, SKC, Eighty Four, PA).

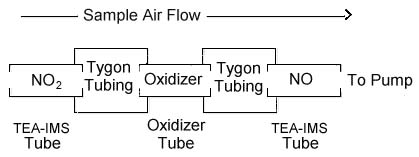

- The other type, a three-tube sampling device

(NO/NO2 sampling tubes, Cat. No.

226-40-special order, water-washed, SKC, Eighty Four, PA) can be

used to sample NO2 and NO simultaneously or

individually. The device consists of three

flame-sealed glass tubes. Nitrogen dioxide is

collected in the first tube which contains 400 mg

TEA-IMS. Two other tubes, an oxidizer tube and

another 400 mg TEA-IMS packed tube, are also

included. The dimensions of each TEA-IMS tube are

7-mm o.d., 5-mm i.d., and

70-mm long. A 3-mm portion of

silylated glass wool is placed in the front and rear of each

tube. An oxidizer tube containing approximately 1 g of a

chromate compound is used to convert NO to NO2. The

dimensions of the oxidizer tube are 7-mm o.d.,

5-mm i.d., and 110-mm long. When the

three tubes are connected in series as shown below,

NO2 and NO can be collected simultaneously.

THREE-TUBE SAMPLING DEVICE

|

| Text

Version: The first tube in the Three-Tube Sampling Device

is a nitrogen dioxide (NO2) sampling tube

(TEA-IMS Tube). The second tube in the series is an

oxidizer tube, and the third is another NO2

sampling tube that is identical to the first

tube. The three tubes are connected with short

lengths of plastic tubing (Tygon or equivalent). The

three tubes should be connected as close to one another as

possible. The sampling device is connected to the

sampling pump with flexible plastic tubing. The set

of three tubes that compose the sampling device is

available from SKC, Inc. as catalog 226-40.

|

For further information regarding

sampling for NO, see reference 8.10.

5.1.3. A stopwatch and bubble tube or meter are used to

calibrate pumps. A sampling tube or device is placed

in-line during flow rate calibration.

5.1.4. Various lengths of Tygon tubing are used to

connect sampling tubes to pumps. 5.2. Sampling Procedure

Note: If sampling for both NO2 and NO is necessary,

two separate pumps and sampling devices should be used. The

differences in OSHA Final Rule PELs (NO2 is a STEL and

NO is a TWA PEL) and flow rates dictates a need for a singular

assessment of NO2. Nitric oxide is collected at a flow

rate not to exceed 0.025 L/min (8.9.-8.10.)

and a three-tube device must be used. Nitrogen

dioxide can be collected at this flow rate; however, a longer

sampling time will be necessary to collect a detectable amount of

NO2 than for a short-term measurement.

Also, NO2 concentrations may vary widely during

sampling periods as long as 4 hours for NO. The

three-tube sampling device will not reflect the

varying concentration. Therefore, it is recommended to sample at

0.2 L/min for 15-min intervals using a single or two

section tube for NO2. A

separate three-tube device and pump is then used

for NO sampling. The front tube of the

device can be submitted for NO2 analysis; however,

results from this front section may not represent

short-term exposures.

5.2.1. Calibrate the sampling pumps at either

recommended flow rate listed in Section 5.2.4.

5.2.2. Connect the sampling tube or device to the pump.

The different sampling schemes are listed below:

- Sampling for NO2 only:

A single TEA-IMS tube taken from the

three-tube sampling device (Section 5.1.2.,

part b) or the two-section tube (Section 5.1.2.,

part a) can be used. If the two-section tube is

used, sampled air should enter the 400 mg section first.

- Sampling for both NO and

NO2: The three-tube device

(Section 5.1.2.,

part b) is used. Label the first tube "NO2". The

tube following the oxidizer section is labeled "NO". Also

consult reference 8.10.

5.2.3. Place the sampling tube

or device in the breathing zone of the employee.

5.2.4. Sample with pre-calibrated

pumps at the listed flow rates and sampling times:

- For NO2 only: 0.2 L/min

for at least 15 min per sample.

- For both NO and NO2:

0.025 L/min for 4 h per sample. Also consult reference 8.10.

Nitrogen dioxide results from extended sampling times

(>15 min) may not reflect short-term

exposures.

5.2.5. The minimum recommended

total air volume for collecting NO2 is 3 L.

6. Analysis

6.1. Precautions

6.1.1. Refer to instrument and standard operating

procedure (SOP) (8.15.)

manuals for proper operation.

6.1.2. Observe laboratory

safety regulations and practices.

6.1.3. Sulfuric acid

(H2SO4) can cause severe burns. Wear

protective gloves and eyewear when using concentrated

H2SO4. 6.2.

Equipment

6.2.1. Ion chromatograph (Model 2010 or 4000,

Dionex, Sunnyvale, CA) equipped with a conductivity detector.

6.2.2. Automatic sampler (Model AS-1,

Dionex) and sample vials (0.5 mL).

6.2.3. Data

processing system: Ion chromatograph interfaced to a data

reduction and control system (AutoIon 400 or 450 System,

Dionex).

6.2.4. Printer.

6.2.5. Separator and

guard columns, anion (Model HPIC-AS4A and AG4A,

Dionex).

6.2.6. Micromembrane suppressor, anion (Model

AMMS-1, Dionex).

6.2.7. Disposable syringes

(1 mL) and pre-filters.

Note: Some syringe pre-filters are not

cation- or anion-free. Tests should be

done with blank solutions first to determine suitability for the

analyte being determined.

6.2.8. Erlenmeyer flasks, 25-mL, or

scintillation vials, 20-mL.

6.2.9. Miscellaneous

volumetric glassware: Micropipettes, volumetric flasks,

graduated cylinders, and beakers.

6.2.10. Analytical

balance (0.01 mg). 6.3. Reagents -

All chemicals should be at least reagent grade.

6.3.1. Deionized water (DI H2O) with a

specific conductance of less than 10 microsiemens.

6.3.2. Triethanolamine

[(HOCH2CH2)3N]

sodium carbonate

(Na2CO3)

sodium bicarbonate

(NaHCO3)

sulfuric acid

(H2SO4, concentrated 95 to

98%)

sodium nitrite (NaNO2)

6.3.3. Liquid desorber (1.5% TEA):

Dissolve

15 g TEA in a 1-L volumetric flask which contains

approximately 500 mL DI H2O. Add 0.5 mL

n-butanol and then dilute to volume with DI

H2O.

6.3.4. Eluent (2.0 mM

Na2CO3/1.0 mM NaHCO3):

Dissolve 0.848 g Na2CO3 and 0.336

g NaHCO3 in 4.0 L of DI H2O.

6.3.5. Regeneration solution (0.02 N

H2SO4):

Place 1.14 mL concentrated

H2SO4 into a 2-L volumetric

flask which contains about 500 mL DI H2O. Dilute to

volume with DI H2O.

6.3.6. Nitrite stock

standard (1,000 µg/mL):

Dissolve 1.5000 g

NaNO2 and dilute to the mark in a 1-L

volumetric flask with DI H2O. Prepare every 3 months.

6.3.7. Nitrite standard (100 µg/mL):

Dilute 10

mL of the 1,000 µg/mL nitrite stock standard to 100 mL with

liquid desorber. Prepare monthly.

6.3.8. Nitrite

standard (10 µg/mL):

Dilute 10 mL of the 100 µg/mL

nitrite stock standard to 100 mL with liquid desorber. Prepare

weekly.

6.3.9. Nitrite standard (1 µg/mL):

Dilute 10 mL of the 10 µg/mL nitrite stock standard to

100 mL with liquid desorber. Prepare daily.

6.4. Working

Standard Preparation

6.4.1. Nitrite working standards

(10-mL final volumes) may be prepared in the ranges specified

below:

Working Std

µg/mL

|

Standard

Solution µg/mL

|

Aliquot

mL

|

0.5

1

3

6

10

20 |

1

1

10

10

10

100 |

5

*

3

6

*

2 |

*

Already prepared in Section 6.3. |

6.4.2. Pipette appropriate aliquots of standard

solutions (prepared in Section 6.3.)

into 10-mL volumetric flasks and dilute to volume

with liquid desorber.

6.4.3. Pipette a 0.5- to 0.6-mL

portion of each standard solution into separate automatic

sampler vials. Place a 0.5-mL filter cap into each

vial. The large exposed filter portion of the cap should face

the standard solution.

6.4.4. Prepare a reagent blank

from the liquid desorber solution. 6.5. Sample Preparation

Note: For NO sample analysis and result calculations, see

reference 8.10.

6.5.1. Clean the 25-mL Erlenmeyer

flasks or scintillation vials by rinsing with DI H2O.

6.5.2. Carefully remove the glass wool plugs from the

sample tubes, making sure that no sorbent is lost in the

process. If the two-section tube was used for

sampling, transfer each TEA-IMS section to

individual 25-mL Erlenmeyer flasks or scintillation

vials. Analyze these two sections separately. If a single

section tube was used, transfer that section to an individual

25-mL Erlenmeyer flask or scintillation vial.

6.5.3. Add 3 mL of liquid desorber to each flask or

vial, shake vigorously for about 30 s and allow the solution to

settle for at least 1 h.

6.5.4. If the sample solutions

contain suspended particulate, remove the particles using a

pre-filter and syringe. Fill the

0.5-mL automatic sampler vials with sample

solutions and push a 0.5-mL filtercap into each

vial. Label each vial.

6.5.5. Load the automatic sampler

with labeled samples, standards and blanks.

6.6. Analytical Procedure

Set up the ion chromatograph and analyze the samples in

accordance with the SOP (8.15.).

Typical operating conditions for equipment mentioned in Section 6.2.

are listed below.

Ion chromatograph

|

|

| Eluent: |

2.0 mM Na2CO3 / 1.0

mM NaHCO3 |

| Column temperature: |

ambient |

| Sample injection loop: |

50 µL |

| |

Pump

|

| Pump pressure: |

approximately 1,000 psi |

| Flow rate: |

2 mL/min |

| |

Chromatogram

|

| Run time: |

6 min |

| Average retention time: |

approximately 2

min | 7. Calculations

7.1. Obtain hard copies of chromatograms from a

printer. A typical chromatogram is shown in Figure

1.

7.2. Prepare a concentration-response

curve by plotting the concentration of the standards in µg/mL (or

µg/sample if the same solution volumes are used for samples and

standards) versus peak areas or peak heights.

7.3. Blank

correct the samples by subtracting the g/mL

NO2- found in the blank from the µg/mL

NO2- found in the samples. If a different solution

volume was used for blanks and samples, use total micrograms

NO2- to blank correct.

7.4.

Calculate the concentration of nitrogen dioxide in each air sample

in ppm. A concentration-dependent conversion factor

is used. The equation is:

| ppm NO2 = |

Molar volume ×

µg/mL NO2- × Solution volume ×

Conversion

Formula weight × Air volume | .

| Where: |

| Molar volume |

= |

24.45 (25 °C and 760 mmHg) |

| µg/mL

NO2- |

= |

blank corrected sample result |

| Formula weight

(NO2) |

= |

46.01 |

| Conversion |

= |

varies with

concentration |

The conversion of gaseous NO2 to

NO2- is concentration-dependent

and should be calculated using one of the equations given below:

From

0 to 10 ppm, the average relationship has

been experimentally determined to be (8.1.-

8.4.,

8.6.-8.9.):

1 µg

NO2 (gas) = 0.63 µg

NO2-

or conversely:

1

µg NO2- = 1.587 µg

NO2 (gas)

Simplifying the equation and

using a 3-mL sample volume gives:

| ppm nitrogen dioxide =

|

µg/mL

NO2- × 3 mL ×

0.843

Air volume (L) |

Above 10 ppm NO2

|

Above 10 ppm NO2, the expected

stoichiometric factor of 0.5 mole of nitrite to 1 mole of nitrogen

dioxide gas is seen (8.6.,

8.8.-8.9.).

Therefore, the following calculation should be used for sample

results above 10 ppm and a

3-mL sample volume:

| ppm nitrogen dioxide = |

µg/mL

NO2- × 3 mL 1 ×

1.063

Air volume (L) |

7.5. Reporting Results

Report all results to

the industrial hygienist as ppm nitrogen dioxide.

8.

References

8.1. National

Institute for Occupational Safety and Health: NIOSH Manual of Analytical Methods, 2nd ed.,

Vol. 4 (HEW/NIOSH Pub. No. 78-175). Cincinnati, OH,

1978.

8.2. Saltzman,

B.E.: Colorimetric Microdetermination of Nitrogen Dioxide

in the Atmosphere. Anal. Chem. 26:1949 (1954).

8.3.

Blacker, J.H.: Triethanolamine for

Collecting Nitrogen Dioxide in the TLV Range. Am. Ind. Hyg. Assoc. J. 34:390 (1973).

8.4.

Occupational Safety and Health Administration

Analytical Laboratory: OSHA Analytical

Methods Manual (USDOL/OSHA-SLCAL Method No.

ID-109). Cincinnati, OH: American Conference of

Governmental Industrial Hygienists (Pub. No. ISBN:

0-936712-66-X), 1985.

8.5.

Chang, S.K., R. Kozenianskas and G.W.

Harrington: Determination of Nitrite Ion Using Differential

Pulse Polarography. Anal. Chem.

49:2272-2275 (1977).

8.6. Gold, A.:

Stoichiometry of Nitrogen Dioxide Determination in Triethanolamine

Trapping Solution. Anal. Chem.

49:1448-50 (1977).

8.7. Vinjamoori, D.V.

and Chaur-Sun Ling: Personal Monitoring Method

for Nitrogen Dioxide and Sulfur Dioxide with Solid Sorbent

Sampling and Ion Chromatographic Determination. Anal. Chem. 53:1689-1691 (1981).

8.8. Occupational Safety and

Health Administration Technical Center: Nitrogen Dioxide Backup Report

(ID-182), by J.C. Ku. Salt Lake City, UT.

Revised 1991.

8.9. Occupational Safety and Health Administration Technical

Center: Nitric Oxide Backup Data Report

(ID-190), by J.C. Ku

(USDOL/OSHA-SLTC Method No. ID-190).

Salt Lake City, UT, Revised 1991.

8.10.

Occupational Safety and Health Administration

Technical Center: Nitric Oxide in

Workplace Atmospheres, by J.C. Ku

(USDOL/OSHA-SLTC Method No. ID-190).

Salt Lake City, UT. Revised 1991.

8.11.

National Institute for Occupational Safety and

Health: Criteria for a Recommended

Standard...Occupational Exposure to Oxides of Nitrogen (Nitrogen

Dioxide and Nitric Oxide) (HEW/NIOSH Pub. No.

76-149). Cincinnati, OH, 1976.

8.12. Berkow, R. and JH. Talbott,

ed.: The Merck Manual. 13th ed.

Rahway, NJ: Merck, Sharp and Dohme Research Laboratories, 1977.

pp. 629-630.

8.13. Proctor, N.B. and J.P. Hughes: Chemical Hazards of the Workplace.

Philadelphia, PA: J.B. Lippincott Company, 1978. pp.

382-383.

8.14. American Conference of Governmental Industrial

Hygienists: Documentation of the

Threshold Limit Values and Bioloical Exposure Indices. 5th

ed. Cincinnati, OH: ACGIH, 1986. pp. 435-436.

8.15. Occupational

Safety and Health Administration Technical Center: Standard Operating Procedure-Ion

Chromatography. Salt Lake City, UT. In progress

(unpublished).

Chromatogram of a

10 µg/mL Nitrate Standard in 1.5% TEA

Solution

|

PEAK

NUM |

RET

TIME |

PEAK

NAME |

AREA |

|

1

2

3

4

5

6 |

0.90

1.15

1.50

1.80

2.13

4.18 |

chloride

nitrile

|

1.778e+004

1.965e+004

2.214e+004

3.476e+003

8.886e+004

3.600e+003 |

|

| |

| |