|

| Method no.: |

ID-105 |

| |

|

| Matrix: |

Air, Wipes (Smear Tabs), or

Bulks |

| |

|

OSHA Permissible Exposure

Limit: |

0.01 mg/m3 |

| |

|

| Collection Procedure: |

Inorganic arsenic1

particulate in the air is collected by drawing a known volume of the

air through a 0.8-µm mixed-cellulose ester

(MCE) filter and backup pad using a calibrated personal sampling

pump. A chemically-treated backup pad is used if

volatile inorganic arsenic species are suspected. If arsine is also

suspected, a sampling train is used (see Section 5). Wipe and bulk

materials are collected using grab sampling techniques. |

| |

|

Recommended Air Volume

Ranges

MCE Filter:

Sampling

Train (Section 5): |

I480 L to 960 L

120 to 240

L |

| |

|

Recommended Sampling Rates

MCE Filter:

Sampling Train (Section 5): |

2.0 L/min

0.5 L/min |

| |

|

| Analytical Procedure: |

Air filters, backup pads, wipes (smear

tabs), and bulks are digested with nitric acid and stabilized by

addition of nickel. After digestion, a small amount of hydrochloric

acid is added. Arsine collected on charcoal is extracted using a

dilute nitric acid/nickel solution. All samples are then diluted to

volume and analyzed by atomic absorption spectroscopy using a heated

graphite atomizer. |

| |

|

Detection Limits

Qualitative:

Quantitative: |

0.003 µg/mL arsenic

0.01 µg/mL

arsenic |

| |

|

Precision and Accuracy

Validation Level:

CVT

Bias

Overall Error |

0.006 to 0.04 mg/m3

0.10

+0.004

±20% |

| |

|

| Method Classification: |

Validated Analytical Method |

| |

|

| Chemist: |

Steven Edwards |

| |

|

| Date (Date Revised): |

1982 (May, 1991) |

| |

|

| 1 |

Inorganic arsenic means copper acetoarsenite

and all inorganic compounds containing arsenic (except arsine)

and measured as arsenic (8.1.). | |

| |

|

Commercial manufacturers and products mentioned in this method are

for descriptive use only and do not constitute endorsements by

USDOL-OSHA.

Similar products from other sources can be

substituted.

|

| |

|

Division of Physical Measurements and Inorganic

Analyses

OSHA Technical Center

Sandy, Utah

|

1.

Introduction

1.1. Scope

This method

describes the collection and analysis of inorganic arsenic for

airborne, wipe, and bulk material samples. Air samples can be

taken for particulate and volatile inorganic arsenic. Sample

preparation at the laboratory involves mineral acid digestion and

nickel stabilization. The analysis is performed with an atomic

absorption spectrometer (AAS) utilizing a heated graphite atomizer

(AAS-HGA). Additional analytes (Cd, Cu, Fe, Pb, and

Zn) can also be analyzed from the same sample media using flame

AAS techniques.

In addition, samples previously prepared

for ICP analysis by OSHA method no. ID-125G (8.2.)

can also be determined for arsenic using the analytical technique

described herein.

1.2. History

Previously, arsenic

was analyzed at the OSHA Analytical Laboratory using an arsine

generation procedure (8.3.). The method required special gas

generation equipment and was time-consuming. An early

AAS-HGA method without the addition of nickel as a

stabilizer was considered; however, this approach had decreased

sensitivity, poor reproducibility, and was subject to potential

interferences and loss of arsenic during analysis. The addition of

nickel to samples minimizes these problems by the apparent

formation of a stable nickel arsenide complex (8.4.). This complex

allows the use of a higher charring temperature during

AAS-HGA analysis and minimizes interferences caused

by incomplete volatilization of any organic substances contained

in the sample matrix (8.5.).

Compared to arsine

generation, the AAS-HGA procedure offers the

following advantages:

- a simple digestion procedure,

- increased ability to analyze other analytes from the same

sample,

- a decrease in sample loss and an increase in sample

throughput.

1.3. Analytical Principle

This method uses a HGA with a Zeeman/L'vov configuration

to analyze arsenic and reduce background contributions. Other

background compensation techniques can be used.

1.3.1. The Zeeman electromagnet technique assists in

minimizing background without the use of continuum sources such

as the deuterium arc. A magnetic field is provided during the

analytical atomization step and results in a "splitting" of the

atom's energy levels. The capability of measuring the atomic

absorption with and without the magnetic field applied during

the atomization step provides a "clean" signal. This "clean"

signal is the net difference between the signal produced with

the magnetic field turned off and then on.

1.3.2. The

L'vov platform is a pyrolytically-coated graphite support

inserted into a graphite tube which is also

pyrolytically-coated. This assembly offers a more

uniform temperature distribution inside the graphite tube,

increased sensitivity, and less opportunity for matrix effects

from molecular formation and absorption during atomization.

1.4. Uses

Arsenic has metallurgical

applications in industry where it is used for hardening lead and

enhancing the toughness and corrosion resistance of copper.

Arsenic compounds are used in medicine, glass manufacture, pigment

production, rodent poisons, insecticides, fungicides, weed

killers, semiconductor manufacture, and tanning processes.

1.5. Physical and Chemical Properties (8.6.)

Metallic arsenic is a steel gray, brittle metal, with a

density of 5.7. It also exists as yellow crystal, As4,

having a density of 2.0.

Some physical properties of

arsenic (CAS #7440-38-2) are:

| Atomic weight |

74.9216 |

| Specific Gravity |

5.727 |

| Melting Point |

sublimes without melting at 613 °C |

| Solubility |

insoluble in H2O; soluble in

HNO3 | 2. Range and Detection Limit

(8.7.)

2.1. For this method, the working range is

0.01 to 0.5 µg/mL arsenic. For a 480-L air

volume and 25-mL solution volume, this range permits

quantitation without sample dilution from approximately 0.0005 to

0.03 mg/m3 arsenic.

2.2. Calculated

quantitative detection limits (DL) are:

Sample Type

|

|

Air Vol

|

|

Flow rate

|

|

Solution Vol

|

|

DL

|

| Air |

480 L |

2 L/min |

25 mL |

0.0005 mg/m3 |

| Air |

120 L |

0.5 L/min |

10 mL |

0.0008 mg/m3 |

| Wipe or Bulk |

----- |

------- |

25 mL |

0.25 µg

|

2.3. The range and detection limits of the other

metal analytes (Cd, Cu, Fe, Pb, and Zn) should be unaffected by

this sample preparation. Detection limits and analytical

parameters for these and other elements can be found in references

8.2. or 8.8. 3. Precision and Accuracy

3.1. Previous and recent quality control samples

(8.9.) containing arsenic in the approximate range of 0.5 to 4

times the OSHA PEL (assuming 960-L air volumes), gave

the following data:

|

Sample Set #1

|

|

Sample Set #2

|

| Bias |

-0.024 |

+0.004 |

| CV |

0.097 |

0.10 |

| Overall analytical error |

±21.8% |

±20.0% |

| Analysis period |

2/1982-4/1982 |

1/1989-12/1990 |

| N |

78

|

100

|

| Analytical technique |

HGA/D2

|

HGA/LD2

(5%) HGA/ZL (95%) |

Where:

|

HGA/D2 |

= |

Heated Graphite Atomizer with deuterium

arc background correction. |

| HGA/LD2 |

= |

Heated Graphite Atomizer/L'vov Platform

with deuterium arc with background correction. |

| HGA/ZL |

= |

Heated Graphite Atomizer with Zeeman/L'vov

Platform |

Approximately 95% of the samples from Set #2 were

analyzed using the HGA Zeeman/L'vov platform approach mentioned in

this method. The remaining samples were analyzed with a HGA/L'vov

platform and deuterium arc background correction only. A

significant difference in results was not noted.

3.2.

Recovery data for arsenic analyzed in an "ICP digest" is presented

in reference 8.7. No significant loss of arsenic was noted when

using the "ICP digest" and a HGA equipped with a Zeeman/L'vov

system.

3.3. For precision and accuracy data for other

metals (Cd, Cu, Fe, Pb, and Zn) analyzed with arsenic, also see

reference 8.7. Recoveries for these metals analyzed by flame

atomic absorption were adequate. 4. Interferences

Sampling

Non-volatile organic arsenic-containing

compounds will provide a positive interference when sampling for

particulate arsenic. The industrial hygienist should make note of

any organo-arsenic use in the area sampled.

Analysis

The analysis of arsenic in an "ICP-type digestion"

matrix (8% HCl/ 4% H2SO4 as mentioned in

reference 8.2.) may require the use of significant background

correction due to the contribution from sulfuric acid. In these

cases, it is recommended to minimize background by using a

Zeeman-type graphite furnace assembly with a L'vov

platform inserted in pyrolytically-coated graphite

tubes; other techniques can be used to diminish background effects

provided they are evaluated using spiked samples and analytical

recovery is adequate.

Perchloric acid (HClO4)

should not be used for sample digestions and subsequent analysis

using this analytical technique. Inhibition of the arsenic signal

after digestion of polyvinyl chloride filters and rapid graphite

tube deterioration from HClO4 have been noted (8.10.).

5. Sampling

When other

compounds or elements are known or suspected to be present in the

sampled air, such information should be transmitted with the sample.

Sampling for arsenic in air is dependent on the operation. If the

operation being sampled has the potential for producing inorganic

arsenic vapor and arsine, a sampling train (Sampling Media II) is

used to capture the vapor and particulate. Some examples of

operations potentially producing arsenic vapor are welding and

torching (8.11.). Arsine can be formed from arsenic when sufficient

hydrogen is present with arsenic [i.e. lead-acid

battery manufacturing plants (8.11.)]. Sampling can be accomplished

using one of two different approaches:

Suspected Form

|

Sampling Media

|

|

Flow Rate (L/min)

|

| Particulate ( + Vapor) |

I |

2 |

| Particulate + Vapor

+ Arsine |

II |

0.5 |

If

possible, all samples should be taken for at least 240 min.

5.1. Equipment

5.1.1. Sampling Media I for

particulate arsenic:

Mixed cellulose ester (MCE)

filters (0.8 µm pore size), cellulose backup pads, and two- or

three-piece cassettes, 37-mm diameter,

(part no. MAWP 037 A0, Millipore Corp., Bedford, MA). If

volatile inorganic arsenic is suspected, the following is used:

For sampling particulate and volatile

inorganic arsenic compounds (i.e. heated arsenic

sources): The cellulose backup pad is chemically treated

and the pads and MCE filters are contained in

three-piece cassettes. This chemical treatment

ensures capture of volatile inorganic arsenic in the backup pad

(8.11.). The backup pads are treated using an impregnation

solution:

Pipettes, 0.5 mL

Sodium carbonate

(Na2CO3)

Glycerol

(C3H8O3)

Impregnation

solution [Na2CO3 solution with glycerol]

- prepare by dissolving 4.0 g Na2CO3 in

50 mL deionized water, add 2 mL glycerol, and dilute this

solution to 100 mL with deionized water. Remove

filters from the three-piece cassettes and use the opened

cassettes as supports for backup pad impregnation. Each backup

pad should be resting on the ridge of the middle insert of the

cassette and not in contact with the cassette base. Slowly

pipette 0.5 mL of the impregnation solution over the entire

backup pad, let dry overnight, and then place the MCE filters on

top of the backup pads and assemble the cassettes.

5.1.2. Sampling Media II (for sampling

when arsine is also suspected to be present): Sampling

media I with the chemically treated backup pad is used in series

with an arsine sampling tube. This tube is composed of glass and

contains 400 mg (front) and 200 mg (backup) sections of

activated coconut shell charcoal. This sampling train is

necessary if volatile inorganic arsenic species and arsine are

suspected to be present in the air.

5.1.3. Sampling

pumps capable of sampling at 2 L/min (Sampling Media I) or 0.5

L/min (Sampling Media II).

5.1.4. Assorted flexible

tubing.

5.1.5. Stopwatch and bubble tube or meter for

pump calibration.

5.1.6. Gel bands (Omega Specialty

Instrument Co., Chelmsford, MA) for sealing cassettes.

5.1.7. Scintillation vials, 20 mL, (part no. 74515 or

58515, Kimble, Div. of Owens-Illinois Inc., Toledo,

OH) with polypropylene or Teflon cap liners. If possible, submit

bulk or wipe samples in these vials.

5.1.8. Smear tabs,

(Whatman 50, part no. 225-24, SKC Inc., Eighty Four, PA) for

wipe sampling. 5.2. Sampling Procedure - Air Samples

5.2.1. Place an MCE filter and a cellulose backup

pad in each two- or three-piece cassette. The

backup pad should be chemically-treated if volatile

inorganic arsenic compounds are suspected. Seal each cassette

with a gel band.

5.2.2. Attach calibration sampling

media to the pump using flexible tubing. Depending on the

sampling media in use, follow the sampling scheme shown:

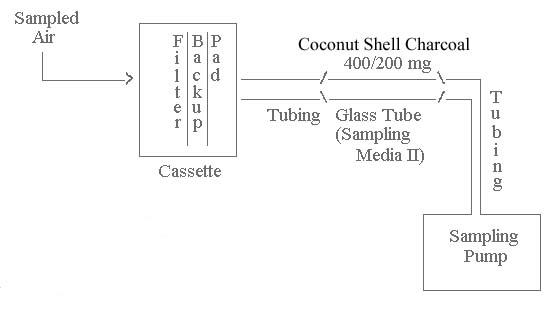

|

| Text Version:

Sampling Media I of the sampling train is a 37-mm mixed

cellulose ester (MCE) filter (0.8 μm pore size) and a

backup pad contained in a two- or a three-piece 37-mm

diameter plastic filter cassette. The backup pad is

chemically treated if volatile inorganic arsenic

substances are suspected to be present. This

treatment for the backup pad is described in Section

5.1.1. The MCE filter and chemically-treated backup

pad are available from SKC, Inc. as catalog no. 225-9001.

The filter cassette is connected to sampling Media II, a

coconut shell charcoal sampling tube (400/200 mg

sections), with a short length of plastic tubing.

The charcoal sampling tube is used if arsene is suspected

to be present. The sampling train is connected to

the sampling pump with flexible plastic

tubing. |

If arsine is suspected, use a

minimum amount of tubing to connect the

cassette to the arsine sampling tube.

5.2.3. Calibrate

each personal sampling pump with prepared sampling media

in-line to within ±10% of the recommended flow rate

of 2 L/min (Sampling Media I) or 0.5 L/min (Sampling Media II).

Remove the calibration media and attach new sampling media to

the calibrated pump.

5.2.4. Place the sampling

media/pump assembly in appropriate positions on the employee or

the workplace area.

5.2.5. If possible, collect

full-shift samples. The minimum recommended air volume is 480 L

(120-L for Sampling Media II). Take samples to

cover the workshift.

5.2.6. If the filter becomes

overloaded while sampling, prepare and use another filter

cassette. Take consecutive samples using shorter sampling

periods if overloading occurs.

5.2.7. Place plastic end

caps on each sampling media after sampling.

5.3. Sampling Procedure -

Wipe Samples

5.3.1. Wear clean, impervious, disposable gloves

when taking each wipe sample.

5.3.2. Moisten the wipe

filters with deionized water prior to use.

5.3.3. If

possible, wipe a surface area covering 100 cm2.

5.3.4. Fold the wipe sample with the exposed side in.

5.3.5. Transfer the wipe sample into a 20-mL

scintillation vial and seal with vinyl or electrical tape.

5.4. Sampling Procedure - Bulk Samples

In

order of laboratory preference, bulk samples may be one of the

following:

- a high-volume filter sample,

- a representative settled dust (rafter) sample,

- a sample of the bulk material in the workplace.

Transfer the bulk material into a

20-mL scintillation vial and seal with vinyl or electrical tape.

5.5. Shipment

5.5.1. Submit at least one blank sample with each

set of air, charcoal, or wipe samples. Blank samples should be

handled in the same manner as other samples, except that no

monitoring is performed with these samples.

5.5.2.

Attach an OSHA-21 seal around each cassette, scintillation vial,

and glass tube (if used) in such a way as to secure the end

caps. Document the industrial operation(s) the samples were

taken from. Send the samples along with any blank samples to the

laboratory with the OSHA-91A paperwork requesting

arsenic analysis. Also note whether volatile

arsenic or arsine was suspected and which Sampling Media was

used.

5.5.3. If desired, specify other elements

of interest. At the OSHA Technical Center the following elements

are analyzable on the same filter, wipe, or bulk with arsenic:

Technique

|

|

Element

|

|

| Atomic Absorption |

Cd, Cu,

Fe, Pb, Zn |

|

| ICP |

Be,

Cd, Cr, Co, Cu, Fe, Mn,

Mo, Ni, Pb, Sb, V,

Zn |

Choose any combination of three elements

listed for Atomic Absorption or choose arsenic/ICP analysis if

more than three elements are desired.

5.5.4. The type of

bulk sample should be stated on the OSHA-91A and

cross-referenced to the appropriate air sample(s).

5.5.5. Ship bulk samples separately from air samples.

They should be accompanied by Material Safety Data Sheets, if

available. Check current shipping restrictions and ship to the

laboratory by the appropriate method.

6. Analysis

6.1. Safety Precautions

6.1.1. Arsenic is considered a human carcinogen

(8.1., 8.6.). Use extreme care when handling arsenic or

arsenic-containing compounds.

6.1.2. All

work with concentrated acids is potentially hazardous. Care

should be exercised when handling any acidic solutions. Acid

solution contact with work surfaces should be avoided. If any

acid contacts the eyes, skin, or clothes, flush the area

immediately with copious amounts of water. Medical treatment may

be necessary.

6.1.3. Always wear safety glasses and

protective clothing when using chemicals. Prepare all mixtures,

samples, or dilutions in an exhaust hood. To avoid exposure to

acid vapors, do not remove any beakers

from the hoods until they have returned to room temperature and

have been diluted.

6.1.4. Use a pipette bulb, never

pipette by mouth.

6.1.5. When scoring glass sampling

tubes to remove the sorbent before analysis, score with care.

Apply only enough pressure to scratch a clean mark on the glass.

Use a paper towel or cloth to support the opposite side while

scoring. Moisten the mark with DI H2O and wrap the

tube in cloth before breaking. If the tube does not break

easily, re-score. Dispose of glass in a waste

receptacle specifically designed and designated for

broken-glass.

6.1.6. Consult the Standard

Operating Procedure (SOP) (8.12.) and any instrument manuals

before using any instrument.

6.1.7. Since metallic

elements and other toxic substances are vaporized during HGA

operation, it is imperative that an exhaust hood is installed

and used directly above the graphite furnace. Always ensure the

exhaust system is operating before proceeding with the analysis.

6.1.8. Do not look directly at the furnace during the

atomization step or at the emission of an electrodeless

discharge lamp.

6.2. Equipment

6.2.1. Atomic absorption

spectrophotometer consisting of a(an):

- Heated graphite furnace atomizer with argon purge system

and graphite tubes

| Note: |

If samples are analyzed in matrices

other than recommended in this method (4% HNO3,

200 µg/mL Ni), or matrix-matching samples and standards is

difficult, it is recommended to use an HGA capable of

significant resolution of background, such as a

Zeeman/L'vov Platform-type HGA

(Perkin-Elmer, Norwalk, CT) with

pyrolytically-coated graphite

tubes. |

- Pressure-regulating devices capable of maintaining

constant argon purge pressure.

- Optical system capable of isolating the desired wavelength

of radiation.

- Adjustable slit.

- Light measuring and amplifying device.

- Display, strip chart, or computer interface for indicating

the amount of absorbed radiation.

- Deuterium Arc Background Corrector (if Zeeman background

correction is unavailable).

- Electrodeless Discharge Lamp (EDL) for arsenic and an EDL

power supply (Note: A modulated system is necessary when using

a Zeeman HGA.).

- Automatic sampler.

6.2.2.

Glassware

- Phillips beakers, 125- and 250-mL

- Volumetric flasks, Class A: 10-, 25-, 50- and 100-mL

- Pipettes, Class A: Assorted sizes

- Scintillation vials, 20-mL (for desorbing charcoal)

6.2.3. Forceps.

6.2.4.

Exhaust hood and hotplate, or microwave digestion system (model

no. MDS-81, CEM Corp., Matthews, NC).

6.2.5. Filtering apparatus consisting of MCE filters,

0.45-µm pore size, 47-mm diameter (cat. no. HAWP

047 00, Millipore Corp., Bedford, MA) and filtering apparatus

(cat. no. XX15 047 00, Millipore).

6.2.6. Automatic

pipets, adjustable, 0.1 to 5.0 mL range (models P-1000 and

P-5000, Rainin Instruments Co., Woburn, MA).

6.2.7. Glass tube scorer, or needle, 21 to 25 gauge -

for glass wool, foam, and sorbent from glass tubes. A piece of

bent wire can also be used.

6.2.8. Exhaust vent.

6.2.9. Ultrasonic bath (for arsine samples).

6.2.10. Analytical balance (0.01 mg).

6.2.11.

Arsine sampling media (for standard preparation if arsine has

been collected): Obtain six sampling tubes each

containing 400 mg (front) and 200 mg (backup) sections of

activated coconut shell charcoal. 6.3. Reagents (All chemicals should be reagent grade

or better.)

6.3.1. Deionized water (DI H2O) with a

specific conductance of less than 10 µS.

6.3.2. Mineral

acids (used for digestions and dilution solution preparation)

CAUTION: Refer to Sections 6.1.2.-6.1.3. before

using acids.

- Hydrochloric acid (HCl), concentrated (36.5 to 38%).

- Nitric acid (HNO3), concentrated (69 to 71%).

6.3.3. Mineral acids (used for

cleaning glassware)

CAUTION: Refer to Sections

6.1.2.-6.1.3. before using acids.

- Nitric acid, 1:1 HNO3/DI H2O

mixture: Carefully add a measured volume of concentrated

HNO3 to an equal volume of DI H2O.

- Nitric acid 10% v/v: Carefully add 100 mL of concentrated

HNO3 to 500 mL of DI H2O and then dilute

to 1 L.

6.3.4. Nickelous nitrate

[Ni(NO3)2·

6H2O].

6.3.5. Stabilizer, 1,000 µg/mL Ni

solution - Dissolve 5.0 g nickelous nitrate in 100 mL of DI

H2O, add 5 mL concentrated HNO3, and

dilute to 1-L with DI H2O.

6.3.6. Mixed cellulose ester (MCE) filters, 0.8-µm pore

size, 37-mm diameter.

| (Note: |

These filters are used for

matrix-matching standards with samples. If possible, use

the same brand and lot of filters for air sampling and

matrix-matching.) |

6.3.7. Diluting solution: Place 20 blank

MCE filters in a cleaned 250-mL Phillips beaker and

carefully add 100 mL of concentrated HNO3 and

100 mL of the 1,000 µg/mL nickel solution. Digest this mixture

on a hot plate until about 20 to 40 mL of solution remain.

Transfer the solution to a cleaned 500-mL

volumetric flask, add 2 mL of concentrated HCl, and dilute to

volume with DI H2O.

6.3.8. Standard solution,

1,000 µg/mL arsenic: If possible, use commercially available

aqueous standards. Observe expiration dates; if none, properly

dispose the standard after 1 year.

6.3.9. If a

commercial standard (Section 6.3.8.) is not available, a 1,000

µg/mL solution can be prepared as follows:

- Sodium hydroxide (NaOH).

- Arsenic trioxide (As2O3).

- Sodium hydroxide, 10% solution: Dissolve 10 g of NaOH in

about 75 mL of DI H2O. Dilute to 100 mL.

In a cleaned 1-L volumetric

flask, dissolve 1.320 g As2O3 in 25 mL 10%

NaOH. Dilute to volume with DI H2O, and mix. Dispose

of properly after 1 year.

6.3.10. Argon, compressed gas

(for HGA tube purges). 6.4. Glassware Preparation

6.4.1. Place the Phillips beakers in an exhaust hood

and add approximately 10 mL of a 1:1 HNO3/DI

H2O mixture in each 125- or 250-mL

Phillips beaker. Using a hot plate, apply moderate heat to the

beakers until refluxing occurs. Carefully decant the acid

mixture into a waste container and allow the beakers to cool

before removing from the hood. Rinse the beakers thoroughly with

DI H2O.

6.4.2. Rinse all volumetric flasks

with 10% v/v HNO3 and then rinse thoroughly with DI

H2O.

6.4.3. Allow all glassware to air dry

before proceeding. 6.5. Standards

6.5.1. Dilute stock solutions:

Prepare

dilute arsenic stock solutions (0.1-, 1-, and 10-µg/mL) by

diluting aliquots of the 1,000-µg/mL standard

solution with DI H2O. Prepare the diluted stock

solutions on the same day the working standards are prepared.

6.5.2. Working standards:

A dilution scheme

using 0.1-, 1-, and 10-µg/mL stock solutions is

proposed below.

Working

Standard

(µg/mL) |

Stock

Solution

(µg/mL) |

Stock solution

Aliquot

(mL) |

Final Volume*

(mL) |

|

0.01

0.02

0.05

0.1

0.2

0.5 |

0.1

0.1

1

1

10

10 |

10

20

5

10

2

5 |

100

100

100

100

100

100 |

|

| * Diluent is the

diluting solution (Section 6.3.7.) |

Dilute all working standards to volume

using the diluting solution. This will assure the matrix (acid,

sample filter, and nickel content) of the samples (air and wipe)

and standards are closely matched. Dispose working standards

after 6 months.

6.5.3. Standards for arsine

determinations

Remove the 400-mg section of charcoal

sorbent from six arsine sampling tubes. Place each

400-mg section in a separate vial. Pipet a

3-mL aliquot from each working standard (prepared

in Section 6.5.2.) into each vial such that six standards

ranging in concentration from 0.01 to 0.5 µg/mL arsenic are

prepared with a charcoal matrix.

6.6. Sample Preparation

| Note: |

Always prepare blank samples with every

sample set. Prepare an additional blank media sample any

time an extra procedure is used (i.e. wiping out the

particulate contained inside a cassette with an MCE filter

or preparing a contaminated backup pad). If possible, this

blank media should be from the same manufactured lot as

the prepared filter, tube, or backup

pad. |

- Preparation of air and wipe sample

filters

- Open the filter cassette or scintillation vial,

carefully remove the sample filter with forceps, and place

in a labeled Phillips beaker. Use 125-mL

beakers for air samples and smear tabs. If the cassette or

vial contains loose dust, carefully rinse the dust into the

beaker with DI H2O. If necessary, wipe out the

dust with a clean MCE filter and place this filter in the

sample beaker.

- Prepare and analyze backup pads if:

- volatile inorganic arsenic species are suspected, or

- the backup pad appears to be discolored. Discoloration

may be due to leakage of air around the filter during

sampling.

If analysis of the backup pad is

necessary, place each backup pad in a separate beaker.

- Preparation of bulk samples

- Review any available material safety data sheets to

determine safe bulk handling. The data may also offer a clue

regarding the aliquot amount needed for adequate detection.

- Measure by volume or weight an appropriate aliquot of

any liquid bulk sample. Weigh the appropriate amount of any

solid bulk sample.

| Note: |

Aliquot amounts of bulks are dependent

on the analytical sensitivity, detection limit, and

solubility of the material used. If uncertain, a 20- to

50-mg aliquot of a solid material can be

taken as a starting point. Make sure the aliquot taken is

representative of the entire bulk sample. If necessary,

use a mortar and pestle to grind any nonhomogenous

particulate bulk samples in an exhaust

hood. |

After measuring, transfer the aliquot to a 250-mL Phillips

beaker.

- Preparation of arsine (charcoal)

samples

- Score the tube with a glass tube cutter (also see

Section 6.1.5.) and then break open the front section of the

tube above the glass wool. An alternative approach to

scoring and breaking is to carefully remove the glass wool

with a bent wire or needle.

- Carefully transfer each section of the sorbent to

separate 20-mL scintillation vials without losing any

particles.

6.7. Sample

Digestion or Extraction

- MCE air filters and smear tabs

Place the beakers in an exhaust hood and carefully add

3 to 5 mL concentrated HNO3 and the appropriate

amount of Stabilizer (Section 6.3.5.) as shown below. Place

the beakers on a hot plate and heat the samples until the

appropriate amount of solution remains as shown below.

Air Vol (L)

|

Stabilizer (mL)

|

Digestion Vol

(mL)

|

| <200 |

2.0 |

0.5 |

| ³ 200 |

5.0 |

1.0 |

| Smear tabs |

5.0 |

1.0 |

| Note: |

If the sample solution is not clear, add

a second portion of approximately 1 to 2 mL of

concentrated HNO3. Apply heat until the

appropriate digestion volume listed above remains.

|

Remove the beakers from the hotplate. Allow

beakers to cool, then add 100 µL (~2 drops) of HCl to each and

swirl the contents.

- Polyvinyl chloride filters, or backup

pads

| Note: |

Polyvinyl chloride (PVC) filters are not

routinely used for arsenic sample collection and analysis.

In some cases the industrial hygienist will sample for

total or respirable dust using PVC filters and also submit

these samples for analysis. The PVC filter will not be

completely digested using the acid digestion listed in

this method; rather, the particulate is

acid-extracted from the filter.

Perchloric acid should not be used to digest

arsenic samples collected on PVC filters or backup pads;

low recoveries for arsenic were noted when PVC filters

were digested using an

H2SO4/HCl/HClO4 acid

matrix (8.10.). In addition, graphite tube degradation is

greatly accelerated from perchloric

acid. |

Place the beakers in an exhaust hood and

add the following amount of concentrated HNO3 to

the beakers:

| Backup pads |

|

10 to 15 mL |

| PVC filters |

|

3 to 5

mL |

Follow the digestion procedure mentioned above (Section

6.7., MCE air filters and smear tabs)

and determine the amount of Stabilizer needed, and digestion

volumes. After heating on a hot plate and subsequent cooling,

each PVC filter should be thoroughly rinsed with DI

H2O during quantitative transfer of the sample

solution.

- Bulk samples

If necessary,

use a microwave digestion system to facilitate digestion [For

further information regarding microwave digestion, see the

Microwave Standard Operating Procedure (8.13.)].

Add

10 to 30 mL HNO3, 5 mL of Stabilizer, and place the

beaker on a hot plate. Digest the bulk sample until the

material dissolves and approximately 1 mL of solution remains.

Remove the beakers from the hot plate. Allow beakers to cool,

then add 40 µL (~2 drops) of HCl to each and swirl the

contents.

- Arsine (charcoal) samples

To each scintillation vial add 3 mL of Stabilizer

solution (Section 6.3.5.). Cap and sonicate each vial contents

for 10 min. 6.7.1. Filtration - any solutions samples containing

particulate

Digested samples: If particulate

matter is present after digesting, allow the sample to cool, add

approximately 10 mL DI H2O, then filter the

solution through a 0.45-µm MCE filter. Save the

filtrate for analysis. Repeat the digestion procedure above for

the filter containing the particulate.

Arsine samples:

If particulate is present after extraction (i.e. charcoal

fines), filter the 3-mL solution through a

0.45-µm MCE filter, and analyze the filtrate.

6.7.2. Dilution - all samples

Digested samples: Allow all beakers to cool to

room temperature in an exhaust hood before proceeding. Carefully

add about 5 mL of DI H2O to each beaker, rinsing down

the insides of each beaker. Quantitatively transfer each sample

solution to individual volumetric flasks. Dilute to volume with

DI H2O and mix well. Recommended final sample

solution volumes are:

| Air (³200-L), wipe, and bulk samples |

|

25 mL |

| Air volumes <200-l |

|

10 mL |

Larger dilution volumes can be used for bulk

samples; however, the final solution volume should contain 4%

HNO3 and 200 µg/mL Ni.

Arsine samples:

For charcoal samples, further dilution is not necessary.

6.7.3. Samples previously prepared for

ICP analysis

For samples already prepared and

analyzed using OSHA method no. ID-125G, no

additional sample preparation is necessary.

6.8. Instrument Setup and

Analysis

6.8.1. Set up the spectrometer and HGA according to

the SOP (8.12.) or the manufacturer's instructions. Suggested

parameters for two specific instruments are shown in Appendix A.

- Install an EDL for arsenic and allow to stabilize.

- Optimize conditions such as lamp position, furnace

alignment, etc. as mentioned in the SOP (8.12.).

- Be sure cooling water is circulating around the furnace

before heating it and if deuterium (D2) arc

background correction is used, assure the purge air is

circulating around the D2 components before

lighting the D2 lamp.

- Only for those samples previously

prepared using OSHA Method ID-125G:

Set

up the instrument such that a nickel spike is added to each

sample or standard immediately prior to HGA initiation. A

10-µL aliquot of the sample can be injected, then

overlay 5 µL of Stabilizer (Section 6.3.5.) on the sample

before starting the HGA cycle. Standards prepared in Section

6.5. can be used during analysis of these samples.

6.8.2. Inject an aliquot of a

standard into the HGA and measure the absorbance of the standard

using peak height or area. The standard concentration should be

within the linear range. If possible, compare this absorbance to

a value from a previous analysis. Measure other prepared working

standards first to assure proper instrument operation.

6.8.3. Analyze samples and blanks. Analyze a standard

after every four or five samples. Standards should bracket the

sample concentrations. Standard readings should be within 10 to

15% of the readings obtained at the beginning of the analysis.

6.8.4. If any samples exceed the linear range, dilute

with diluting solution (Section 6.3.7.) to bring them into the

working range.

6.8.5. Cadmium, copper, iron, lead, and

zinc can be analyzed in conjunction with the arsenic analysis

using an atomic absorption spectrophotometer (air/acetylene

flame) and direct aspiration. Analytical conditions for flame

analysis of these elements are shown in Appendix B. Additional

information can be found in OSHA Method No. ID-121

or instrument manufacturers' manuals. 6.9. Analytical Recommendations

6.9.1. The amount of nickel added to each sample can

vary slightly from the standards without producing a significant

matrix effect. An excess of nickel always needs to be present.

(Note: A common range is to have from 100 to 2,000 µg/mL Ni

present in the samples and standards.)

6.9.2. When

standards are prepared, analyze the old and new standards and

compare results to verify the new standard is correct. If two or

more 1,000 µg/mL arsenic solutions are available for standard

preparations, rotate the preparation from one stock solution to

the next to verify the quality.

6.9.3. Keep a permanent

record of all standard preparation and comparison data. Assign

and follow expiration dates for all standards.

6.9.4.

Always analyze blank samples along with the other samples. Treat

blanks in the same fashion as samples, including any filtration

steps.

6.9.5. If possible, analyze quality control

samples from an independent source. The quality control samples

should be freshly prepared if they are derived from liquid

spikes on MCE filters. 7. Calculations

If

sample or standard injection volumes are not constant, the

differences need to be considered before establishing a curve and

calculating results.

7.1. Plot the peak height or area versus the standard

concentrations in µg/mL. Using a least squares method, determine

the equation for the best curve fit.

7.2. Use the equation

to calculate the concentration of arsenic in µg/mL for each

sample.

7.3. Calculate the concentration of each air

sample as:

| C = |

[(A × SA × D) -

(B × SB)]

air volume |

| Where: |

|

C |

= |

arsenic (mg/m3) |

| A |

= |

concn of arsenic in the sample solution

(µg/mL) |

| B |

= |

concn of arsenic in the blank solution

(µg/mL) |

| SA |

= |

sample solution volume (mL) |

| SB |

= |

blank solution volume (mL) |

| D |

= |

sample dilution factor (if any) |

| Air Vol |

= |

air volume sampled

(L) |

7.4. For

wipe or bulk samples, calculate the total amount (in µg) of

analyte in each sample using the equation above without air

volumes. Convert bulk sample analytes to % composition using:

| Arsenic %(w/w)

= |

(C)(100%)

(sample weight)(1000 µg/mg) |

(Bulk

Samples) |

| Where: |

| C |

= |

arsenic amount (µg) |

| Sample wt |

= |

aliquot (in mg) of bulk taken in Section

6.6. |

7.5.

Analytes other than arsenic are calculated in the same fashion as

described above. For the charcoal sampling media results from

Sampling Media II, multiply the arsenic found by 0.326 to obtain

ppm arsine values. For air samples, multiply any results for zinc

or iron by the appropriate gravimetric factor (ZnO/Zn =

1.2447, Fe2O3/Fe =

1.4298).

7.6. With the exception of arsine sample results,

combine results from sampling trains or filtrate/particulate

samples to give a single arsenic result per sample. As examples:

Total As exposure

|

|

Results

|

| Sampling Media I or II |

= |

filter + backup pad* |

| Samples containing undigested

particulate |

= |

filtrate +

redigest |

| * |

If the chemically-treated pad was used or

if the air sample leaked onto the

pad. |

7.7.

Reporting Results to the Industrial Hygienist

7.7.1. Report air sample results as mg/m3

arsenic.

7.7.2. Report wipe sample concentrations as

total micrograms or milligrams arsenic.

7.7.3. Report

bulk sample results as approximate percent by weight arsenic

(Note: Sample results for bulk liquids may be reported as

approximate percent by volume if volumetric aliquots were taken

during sample preparation.) Due to differences in sample

matrices between bulks and standards, bulk results are

approximate.

Analytes other than arsenic are reported in

the same fashion as described above. Arsine results (in ppm) are

reported separately. Air sample results for zinc and iron are

reported to the industrial hygienist as oxides.

8. References

8.1. "Inorganic arsenic," Code of

Federal Regulations 29 CFR 1910.1018. 1989.

142-155.

8.2. Occupational

Safety and Health Administration Technical Center: Metal and Metalloid Particulate in Workplace

Atmospheres (ICP) by J. Septon

(USDOL/OSHA-SLTC Method No. ID-125G).

Salt Lake City, UT. Revised 1991.

8.3. Occupational Safety and Health Administration

Analytical Laboratory: OSHA Manual of

Analytical Methods edited by R.G. Adler (Method No.

I-2). Salt Lake City, UT. 1978.

8.4. Ediger, R.D.: Atomic Absorption Analysis with

the Graphite Furnace using Matrix Modification. Atomic Absorption Newsletter 14(5):

127-130 (1975).

8.5. Edwards, S.E.: "The Determination of Arsenic and

Lead on a Single Personal Air Sample." Paper presented at American

Industrial Hygiene Association National Conference, Houston, TX,

1980.

8.6. Hawley, G.G.: The Condensed Chemical Dictionary. 11th ed.

New York: Van Nostrand Reinhold Co., 1987.

8.7. Occupational Safety and Health Administration Technical

Center: Arsenic Backup Data Report

(ID-105). Salt Lake City, UT. 1991.

8.8. Occupational Safety and Health

Administration Technical Center: Metal

and Metalloid Particulate in Workplace Atmospheres (Atomic

Absorption) (USDOL/OSHA-SLTC Method No.

ID-121). Salt Lake City, UT. Revised 1990.

8.9. Occupational Safety and Health

Administration Technical Center: OSHA

Laboratory Quality Control Division Data by B. Babcock.

Salt Lake City, UT, 1990 (unpublished).

8.10. Occupational Safety and Health Administration

Analytical Laboratory: As on FWSB

filters by ICP digest by C. Merrell. Salt Lake City,

UT. 1989 (unpublished).

8.11. Costello,

R.J., P.M. Eller, and R.D. Hull: Measurement of Multiple

Inorganic Arsenic Species. Am. Ind. Hyg. Assoc.

J. 44(1): 21-28 (1983).

8.12. Occupational Safety and Health Administration Technical

Center: AAS-HGA Standard

Operating Procedure. Salt Lake City, UT. In progress

(unpublished).

8.13. Occupational Safety

and Health Administration Analytical Laboratory: Standard Operating Procedure for Microwave

Digestions. by D. Cook. Salt Lake City, UT. 1989

(unpublished).

Appendix

A

Typical Instrumental Parameters*

|

| Instrument |

Zeeman*

|

PE 5000*

|

|

Wavelenth+

Slit

Signal

Mode

D2 Background Correction

Integration Time

Sample Injection Vol

Automatic sampler |

197.3 nm

0.7 nm

Peak Area

6 s

10 µL

AS60** |

197.3 nm

0.7 nm low

Peak Area

AA-BG/ABS

Yes

6 s

10 µL

AS40** |

| Zeeman* or PE

5000* wiht L'vov Platform |

|

Furnace |

Time |

Internal Argon |

|

Temperature

(°C) |

Ramp

(s) |

Hold

(s) |

Flow

(mL/min) |

|

1) Pre-dry

2)

Dry

3) Char

4) Cool

Down

5) Atomize

6) Burn

out

|

90

140

1,300

30

2,300

2,600 |

5

30

10

1

0

1 |

10

10

20

8

5

6 |

300

300

300

300

0

300 |

|

| * Instruments are: |

| Zeeman |

= |

Model 5100 Zeeman Atomic Absorption

Spectrophotometer equipped with a model 600 HGA controller

(Perkin-Elmer, Norwalk, CT) |

|

| PE 5000 |

= |

Model 5000 Atomic Absorption

Spectrophotometer equipped with a model 500 HGA controller

(Perkin-Elmer) |

|

| ** Model numbers of

automatic samplers (Perkin-Elmer) |

|

| + |

Secondary wavelength is used to

increase the upper linear range. Primary wavelength of 193.7

nm can be used to increase sensitivity; however, a decrease

in the upper range may be

noted. |

Appendix B

Cd, Cu, Fe, Pb, Zn

Analysis |

The following parameters were used for the

validation (8.7.) (atomic absorption-air/acetylene

flame) of Cd, Cu, Fe, Pb, and Zn:

|

| Metal |

Wavelength

(nm) |

Slit Setting

(nm) |

Light

Source |

Comments |

|

Cd

Cu

Fe

Pb

Zn |

228.8

324.7

248.3

283.3

213.9 |

0.7

0.7

0.2

0.7

0.7 |

HCL

HCL

HCL

HCL

HCL |

*

|

HCL = Hollow Cathode Lamp

*

When Fe is determined in the presence of Ni and

HNO3, a reduction in sensitivity is observed. This

effect can be controlled by using a very lean (hot) flame.

All analytes were analyzed using an oxidizing

air/acetylene (lean-blue) flame.

| |