|

| Method no.: |

PV2138 |

| |

|

| Control no.: |

T-PV2138-01-0403-CH |

| |

|

| OSHA PEL: |

500 ppm (2350

mg/m3) |

| |

|

| Procedure: |

Samples are collected

by drawing a known volume of air through glass sampling tubes

containing coconut-shell charcoal. Samples are extracted with

1 mL of a solution of carbon disulfide: N,N-dimethylformamide (99:1) with 0.25

µL/mL p-cymene internal standard,

and analyzed by GC using a flame ionization detector

(FID). |

| |

|

| Recommended sampling

time and sampling rate: |

80 min at 0.05 L/min

(4.0 L) |

| |

|

| Reliable quantitation

limit: |

200 ppb (933

µg/m3) |

| |

|

| Status of method: |

Partially evaluated

method. This method has been subjected to established

evaluation procedures of the Methods Development Team and is

presented for information and trial use. |

| |

|

| |

|

| March 2004 |

Anna

Tang |

| |

|

Chromatography Team

Industrial Hygiene Chemistry

Division

OSHA Salt Lake Technical Center

Sandy, UT

84070-6424

|

1. General

Discussion

1.1 Background

1.1.1 History

OSHA Method 48 for Petroleum Distillates validated

collection of a boiling fraction that contained n-octane

on coconut shell charcoal1.

NIOSH Method 1500 for sampling and analysis of n-octane

requires sample collection on coconut shell charcoal,

extraction with carbon disulfide, and analysis by gas

chromatography with FID detection2.

These two methods were used as a guide for selection of

parameters for this partially-validated method for

n-octane. Storage stability was not assessed in the NIOSH

work. This work was done to confirm the NIOSH evaluation

results using the OSHA partially-validated methods

evaluation protocol and to perform a storage stability

test. Samples in this method are collected with coconut

shell charcoal, extracted with 1 mL of carbon disulfide:

N,N-dimethylformamide (99:1

CS2:DMF) and analyzed by GC/FID. The

extraction, storage, and retention efficiency studies

showed good recoveries.

1.1.2 Toxic effects

(This section is for information only and should not be

taken as the basis of OSHA policy.)3,4

n-Octane is a mucous membrane, eye, and nose

irritant. High concentrations can cause drowsiness,

dermatitis, and narcosis. It is toxic by ingestion,

inhalation, and skin contact.

1.1.3 Workplace

Exposure3

n-Octane has been used as a solvent, in organic

synthesis, and in azeotropic distillations. The octanes

are present in gasoline and petroleum solvents such as

VM&P naphtha.

1.1.4 Physical

properties and other descriptive information3,5

| CAS number: |

111-65-9 |

IMIS6: |

1957 |

| molecular weight: |

114.23 |

vapor density: |

3.86 |

| melting point: |

-56.8°C |

boiling point: |

127°C |

| appearance: |

colorless liquid |

vapor pressure: |

1.4 kPa @20°C |

| odor: |

gasoline |

flash point: |

22°C (72°F) (open cup) |

| solubility: |

soluble in ethyl ether, ethyl alcohol and

benzene |

molecular formula: |

CH3(CH2)6CH3 |

| synonyms: |

normal octane |

density: |

0.7028

g/mL |

structural formula:

This method was evaluated according to the

OSHA SLTC "Evaluation Guidelines for Air Sampling Methods

Utilizing Chromatographic Analysis"7.

The Guidelines define analytical parameters, specify required

laboratory tests, statistical calculations, and acceptance

criteria. The analyte air concentrations throughout this

method are based on the recommended sampling and analytical

parameters.

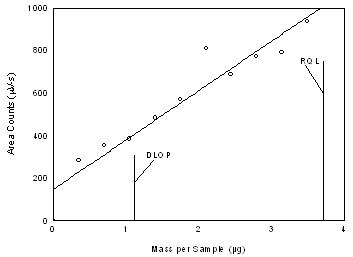

1.2 Detection limit

of the overall procedure (DLOP) and reliable quantitation

limit (RQL)

The DLOP is measured as mass per sample

and expressed as equivalent air concentration, based on the

recommended sampling parameters. Ten samplers were spiked

with equally descending increments of analyte, such that the

highest sampler loading was 3.5 µg of n-octane. This is the

amount spiked on a sampler that would produce a peak about

10 times the response for a sample blank. These spiked

samplers were analyzed with the recommended analytical

parameters, and the data obtained used to calculate the

required parameters (standard error of estimate (SEE) and

slope) for the calculation of the DLOP. The slope was 232.4

and the SEE was 86.2. The RQL is considered the lower limit

for precise quantitative measurements. It is determined from

the regression line parameters obtained for the calculation

of the DLOP, providing 75% to 125% of the analyte is

recovered. The DLOP and RQL were 1.11 µg (59.5 ppb) and 3.71

µg (198.9 ppb), respectively. The recovery at the RQL was

93.8%.

Table 1.2

Detection Limit of the Overall

Procedure

for n-Octane

|

mass per

sample

(µg) |

area

counts

(µV-s) |

|

| 0.00 |

0 |

| 0.35 |

282 |

| 0.70 |

355 |

| 1.05 |

385 |

| 1.40 |

483 |

| 1.75 |

571 |

| 2.10 |

811 |

| 2.44 |

689 |

| 2.79 |

773 |

| 3.14 |

791 |

| 3.49 |

937 |

|

Figure 1.2.1. Plot of data to determine

the DLOP/RQL for n-octane. (y=232.41x + 146.58; SEE =

86.2) |

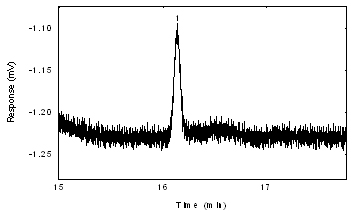

Below is a chromatogram of

the RQL level.

Figure 1.2.2. Chromatogram of the

n-octane peak in a standard. (Key: (1)

n-octane) |

2. Sampling

Procedure

All safety practices that apply to the work

area being sampled should be followed. The sampling equipment

should be attached to the worker in such a manner that it will

not interfere with work performance or safety.

2.1 Apparatus

2.1.1 Samples are

collected using a personal sampling pump calibrated, with

the sampling device attached, to within ±5% of the

recommended flow rate.

2.1.2 Samples are

collected with 7-cm × 4-mm i.d. × 7-mm o.d. glass sampling

tubes packed with two sections (100/50 mg) of charcoal.

The sections are held in place with foam plugs and with a

glass wool plug at the front. For this evaluation,

commercially prepared sampling tubes were purchased from

SKC, Inc. (catalog no. 226-01, lot 2000).

2.2 Reagents

None required.

2.3 Technique

2.3.1 Immediately

before sampling break off the ends of the flame-sealed

tube to provide an opening approximately half the internal

diameter of the tube. Wear eye protection when breaking

the tube. Use tube holders to minimize the hazard of

broken glass. All tubes should be from the same lot.

2.3.2 The smaller

section of the adsorbent tube is used as a back-up and is

positioned nearest the sampling pump. Attach the tube

holder to the sampling pump so that the adsorbent tube is

in an approximately vertical position with the inlet

facing down during sampling. Position the sampling pump,

tube holder, and tubing so they do not impede work

performance or safety.

2.3.3 Draw the air to

be sampled directly into the inlet of the tube holder. The

air being sampled is not to be passed through any hose or

tubing before entering the sampling tube.

2.3.4 After sampling

for the appropriate time, remove the adsorbent tube and

seal it with plastic end caps. Seal each sample end-to-end

with an OSHA-21 form as soon as possible.

2.3.5 Submit at least

one blank sample with each set of samples. Handle the

blank sample in the same manner as the other samples

except draw no air through it.

2.3.6 Record sample

air volumes (liters), sampling time (minutes), and

sampling rate (L/min) for each sample, along with any

potential interferences on the OSHA-91A form.

2.3.7 Submit the

samples to the laboratory for analysis as soon as possible

after sampling. If delay is unavoidable, store the samples

at refrigerator temperature. Ship any bulk samples

separate from the air samples.

2.4 Extraction

efficiency

The extraction efficiency was determined

by spiking front sections of sampling tubes with n-octane at

0.1 to 2 times the target concentration based on 4-L air

samples. These samples were stored overnight at ambient

temperature and then extracted for 30 minutes with shaking,

and analyzed. The mean extraction efficiency over the

studied range was 101.9%.

Table 2.4

Extraction Efficiency (%) of

n-Octane

|

| Level |

|

|

|

|

|

x

target

concn |

mg

per

sample |

1 |

2 |

3 |

4 |

mean |

|

| 0.1 |

0.91 |

95.4 |

98.0 |

99.9 |

99.8 |

98.3 |

| 0.5 |

4.89 |

109.4 |

108.1 |

107.9 |

109.5 |

108.7 |

| 1.0 |

9.08 |

99.5 |

100.2 |

100.2 |

101.1 |

100.3 |

| 2.0 |

18.86 |

100.1 |

100.6 |

100.4 |

100.4 |

100.4 |

|

2.5 Retention

efficiency

Eighteen charcoal sampling tubes were

each spiked with 18.86 mg of n-octane on the front sections.

This mass of n-octane is approximately equivalent to 2 times

the OSHA PEL, based on a 4-L air volume. The test was

performed by pulling humid air (absolute humidity 15.7

milligrams of water per liter of air, about 78% relative

humidity at 23°C) through the tubes at approximately

0.05-L/min for increasing times. Pairs of samples were

removed at approximately 0.5-L increments between 2 and 6-L

and analyzed. The analytical results of the tube front and

back charcoal sections were compared to detect breakthrough.

These results show that the recommended air volume of 4-L,

sampled at 0.05-L/min, provides an adequate safety margin

against sampler saturation. The average of each pair of

samples is presented for the air volumes shown in table

2.5.

Table 2.5

Retention Efficiency (%) of

n-Octane

|

| L of air |

6.09 |

5.59 |

5.15 |

4.57 |

4.03 |

3.56 |

3.07 |

2.52 |

2.04 |

|

| section A |

104 |

105 |

110 |

107 |

107 |

109 |

105 |

106 |

105 |

| section B |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

2.6 Sample

storage

Fifteen charcoal tubes were each spiked with

9.08 mg (500 ppm) of n-octane, then they had 4-L of air,

with an absolute humidity of 15.7 milligrams of water per

liter of air (about 78% relative humidity at 23°C), drawn

through them. Three samples were analyzed immediately, and

the rest were sealed. Six were stored at room temperature

(23°C), and the other six were stored at refrigerated

temperature (4°C). The amounts recovered indicate good

storage stability for the time period studied.

Table 2.6

Storage Test for n-Octane

|

| time

(days) |

ambient storage

recovery (%) |

refrigerated storage

recovery (%) |

|

| 0 |

97.5 |

97.0 |

96.1 |

|

|

|

| 7 |

94.9 |

96.3 |

94.1 |

98.0 |

92.7 |

96.5 |

| 14 |

100.5 |

100.7 |

101.3 |

100.1 |

101.3 |

101.1 |

|

2.7 Recommended

air volume and sampling rate

Based on the data

collected in this evaluation, 4-L air samples should be

collected at a sampling rate of 0.05 L/min for 80

minutes.

2.8 Interferences

(sampling)

2.8.1 There are

no known compounds which will severely interfere with the

collection of n-octane.

2.8.2 Suspected

interferences should be reported to the laboratory with

submitted samples. 3. Analytical

Procedure

Adhere to the rules set down in your

Chemical Hygiene Plan. Avoid skin contact and inhalation of

all chemicals and review all appropriate MSDSs.

3.1 Apparatus

3.1.1 A gas

chromatograph equipped with an FID detector. An Agilent

6890 Plus Gas Chromatograph equipped with a 7683 Injector

was used in this evaluation.

3.1.2 A GC column

capable of separating n-octane from the extraction

solvent, internal standard, and any potential

interferences. A 60-m × 0.32-mm i.d. DB-1 J & W

(5.0-µm df) capillary column was used in this evaluation.

3.1.3 An electronic

integrator or some other suitable means of measuring peak

areas. A Waters Millennium32 Data System was used in this

evaluation.

3.1.4 Glass vials

with poly(tetrafluoroethylene)-lined caps. For this

evaluation 2-mL vials were used.

3.1.5 A dispenser

capable of delivering 1.0 mL of desorbing solvent to

prepare standards and samples. If a dispenser is not

available, a 1.0-mL volumetric pipet may be used.

3.1.6 Volumetric

flasks – 10-mL and other convenient sizes for preparing

standards.

3.1.7 Calibrated

10-µL or 20-µL syringe for preparing standards.

3.1.8 A mechanical

shaker. An Eberbach mechanical shaker was used in this

evaluation.

3.2 Reagents

3.2.1 n-Octane,

reagent grade. ChemService lot FJ8667, 99% was used in

this evaluation.

3.2.2 Carbon

disulfide, reagent grade. EM Science lot 40298103, 99.9%

was used in this evaluation.

3.2.3 N,N-dimethylformamide, reagent grade.

Sigma-Aldrich lot 01340AB, 99.8% was used this evaluation.

3.2.4 p-Cymene, reagent grade. Aldrich lot

306PZ, 99% was used in this evaluation.

3.2.5 The extraction

solvent solution was carbon disulfide: N,N-dimethylformamide (99:1) with

0.25µL/mL of p-cymene as

internal standard.

3.3 Standard

preparation

3.3.1 Prepare

standards by spiking microliter quantities of n-octane

from a microliter syringe into 2-mL vials, each containing

1 mL of the desorbing solution. For example, 13 µL of

n-octane in 1 mL CS2:DMF is equivalent to 9.14

mg/mL. For this evaluation, standards in the range of

0.0003 to 18.9 mg/mL were used. A check standard from a

second source should be prepared to check the calibration.

3.3.2 Bracket sample

concentrations with standard concentrations. If upon

analysis, sample concentrations fall outside the range of

prepared standards, prepare and analyze additional

standards to confirm instrument response, or dilute high

samples with extraction solvent and reanalyze the diluted

samples.

3.4 Sample

preparation

3.4.1 Remove the

plastic end caps from the sample tubes and carefully

transfer each adsorbent section to separate 2-mL vials.

Discard the glass tube, urethane foam plug and glass wool

plug.

3.4.2 Add 1.0

mL of extraction solvent to each vial using the same

dispenser as used for preparation of standards.

3.4.3 Immediately

seal the vials with poly(tetrafluoroethylene)-lined caps.

3.4.4 Shake the vials

on a shaker for 30 minutes.

3.5 Analysis

3.5.1 Gas

chromatographic conditions

GC

conditions

|

|

| Temperature: |

|

| column: |

initial 50°C, hold 3

min, program at 8°C/min to 185 °C, hold 5 min |

| injector: |

225°C |

| detector: |

250°C |

| run time: |

24.6 min |

| column gas flow: |

2.5 mL/min

(hydrogen) |

| septum purge: |

1.9 mL/min

(hydrogen) |

| injection size: |

1.0 µL (10:1

split) |

| column: |

60-m × 0.32 mm i.d.

capillary DB-1 (df = 5.0 µm) |

| retention

times: |

8.3 min (carbon

disulfide)

14.6 min (N,N-dimethylformamide)

16.1

min (n-octane)

22.0 min (p-cymene) |

| Chromatogram: |

Figure 3.5.1. |

| |

|

FID conditions

|

|

| hydrogen flow: |

35 mL/min |

| air flow: |

450 mL/min |

nitrogen

makeup

flow: |

35

mL/min |

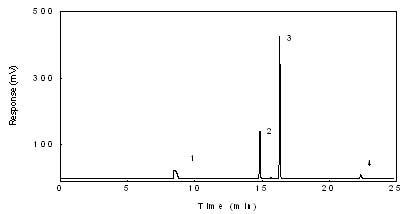

Figure 3.5.1. A chromatogram of 9136

µg/mL n-octane in 99:1 CS2/DMF with 0.25µL/mL

p-cymene

internal

standard. (Key: (1) CS2; (2) DMF; (3)

n-octane; and (4) p-cymene) |

3.5.2 Peak

areas are measured by an integrator or other suitable

means.

3.5.3 An

internal standard (ISTD) calibration method is used. A

calibration curve can be constructed by plotting response

of standard injections versus micrograms of analyte per

sample. Bracket the samples with freshly prepared

analytical standards over the range of concentrations.

Figure 3.5.3. Calibration curve of

n-octane. (y = 482x – 3.73E4) |

3.6 Interferences

(analytical)

3.6.1 Any

compound that produces a GC response and has a similar

retention time as the analyte is a potential interference.

If any potential interferences were reported, they should

be considered before samples are extracted. Generally,

chromatographic conditions can be altered to separate an

interference from the analyte.

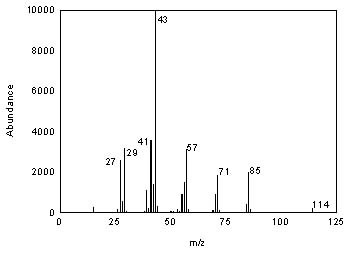

3.6.2 When necessary,

the identity or purity of an analyte peak may be confirmed

by GC-mass spectrometry.

Figure 3.6.2. Mass spectrum of

n-octane. |

3.7 Calculations

The amount of analyte per sampler is obtained from

the appropriate calibration curve in terms of micrograms per

sample, uncorrected for extraction efficiency. This total

amount is then corrected by subtracting the total amount (if

any) found on the blank. The air concentration is calculated

using the following formulas.

| where: |

CM is concentration by

weight (mg/m3) |

| M is micrograms per sample |

| V is liters of air sampled |

| EE is extraction

efficiency, in decimal

form |

| where: |

CV is concentration by

volume (ppm) |

| VM is molar volume at

25°C and 1 atm = 24.46 |

| CM is concentration by

weight |

| Mr is molecular weight

=

114.23 |

4. Recommendations

for Further Study

Collection, reproducibility, and

other detection limit studies need to be performed to make

this a validated method.

References

1.

OSHA Method 48 http://www.osha-slc.gov/

(accessed 11/11/03).

2. NIOSH Method 1500 http://www.osha-slc.gov/pls/oshaweb/owaredirect.html?p_url=http://www.cdc.gov/niosh/homepage.html

(accessed 11/11/03).

3. Documentation of the Threshold

Limit Values and Biological Exposure Indices, 7th

ed., American Conference of Governmental Industrial Hygienists

Inc., Cinncinnati, OH, 2001, Vol. 2.

4. O’ Neil, M.,

The Merck Index, 13th ed. Merck & Co Inc., Whitehouse

Station, NJ, 2001, p. 6775.

5. Lewis, R., Sr., Hawley’s

Condensed Chemical Dictionary, 14th ed., John Willy &

Sons, Inc. NY, 2001, p. 812.

6. OSHA Chemical Sampling

Information, http://www.osha-slc.gov/

(accessed 11/11/03).

7. Burright, D.; Chan, Y.; Edie,

M.; Elskamp, C.; Hendricks, W.; Rose, M.C. Evaluation

Guidelines for Air Sampling Methods Utilizing Chromatographic

Analysis; OSHA Salt Lake Technical Center, U.S. Department of

Labor, Salt Lake City, UT, 1999.

| |