1. General Discussion

1.1 Background

1.1.1 History of

procedure

A set of samples collected on glass fiber filters in

tandem with tenax tubes requesting the analysis of RDX was received at

the OSHA Lab.

This evaluation was undertaken to determine the

effectiveness of a glass fiber filter as a sampling device for RDX.

This study indicates a tenax backup tube is not

necessary.

1.2.1 Toxic effects (This section is for

information only and should not be taken as the basis of OSHA

policy).

Cyclonite is a highly explosive solid, more powerful

than TNT, that found extensive use during World War II. RDX is

desensitized by mixing it with TNT to form cyclotols or by coating it

with waxes, synthetic polymers, and elastomeric binders. RDX made in

the U.S. is converted into either Composition B (60% RDX, 40% TNT, pt

wax) or Composition A3 (RDX 91% wax 9%). (Ref. 5.1-5.2)

The

following paragraph describing the toxicity of RDX is excerpted from

the book Documentation of the Threshold Limit Values. (Ref. 5.2)

The clinical manifestations referable to the central

nervous system of nausea, vomiting, convulsions and unconsciousness

seen in the workers paralleled those previously reported in animals

by von Oettingen and Sunderman. Animals studies show RDX not to be

an acutely toxic substance. Human illness results from repeated

exposures via the respiratory and gastrointestinal tracts and by

skin absorption. The following paragraph describing some

effects and symptoms of RDX were taken from Industrial Hygiene And

Toxicology. (Ref. 5.3)

Epileptiform seizures have occurred in workplace

manufacturing trimethylenetrinitramine (T4)[RDX] in

Italy. The convulsions occurred either without warning or

after 1 or 2 days of insomnia, restlessness, and

irritability. They were generalized tonic-clonic convulsions

resembling in all clinical respects the seizures seem in epilepsy

but occurring in individuals without a previous history of seizures.

They were most frequent in persons doing the drying sieving, and

packing where the dust could be inhaled. The attacks disappeared

when the workers were removed from contact with

trimethylenetrinitramine. The seizures were followed by temporary

post convulsive amnesia, malaise, fatigue, and asthenia but there

was eventually complete recovery. When cyclonite dust

control was maintained below 1.5 mg/m3, relative good

health has been reported. This TLV-TVA value was based on a suggestion

by von Oettingen and co-workers. RDX has been given a TLV-TVA of 1.5

mg/m3 by the ACGIH. (Ref. 5.3)

OSHA adopted this

same value as its PEL in March 1989.

Editorial Note: These March

1989 PELs were vacated on July 7, 1992 and ceased to be enforceable on

March 23, 1993 (FR

58:35338-35351, 6/30/1993).

1.1.3 Potential

workplace exposure

Widespread exposure to workers handling

cyclonite occurred during World War II, and as late as 1962.

No

estimate of worker exposure to RDX since 1962 could be found.

Potential exposure involves those individuals in manufacturing,

formulation, and application of RDX.

1.1.4 Physical

properties (Ref. 5.1-5.6)

| Molecular weight: |

222.26 |

| |

|

| Molecular formula: |

C3H6N606 |

| |

|

| CAS #: |

121-82-4 |

| |

|

| IMIS #: |

2224 |

| |

|

| Melting point: |

205 to 206°C |

| |

|

| Vapor

Pressure: |

Log10pa = 16.26

- 6785/K or

Log pmHg = 14.14 - 6785/K |

| |

|

| Appearance: |

white crystalline

solid |

| |

|

| Solubility: |

One gram in 25 ml acetone;

slightly soluble in acetonitrile, methanol, ether, ethyl

acetate, glacial acetic acid; practically insoluble in water:

carbon tetrachloride, carbon disul-

fide |

| |

|

| Synonyms: |

RDX, Cyclonite, T4 Hexogen

Tri-

methylenetrinitramine,

Cyclotrimeth-

ylenetrinitramine,

l,3,5-trinitro-

hexahydro-s-triazine |

| |

|

| Chemical names: |

Hexahydro-1,3,5-trinitro-1,3,5-triazine |

| |

|

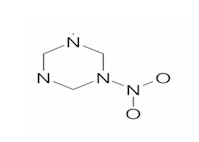

| UV spectrum: |

See Figure 1. |

| |

|

| Stability: |

Stable (stored for 10

months at 85°C

without perceptible deterioration), Class A

explosive (detonation occurs by: sudden shock, high temperature,

or combination of the two) |

| |

|

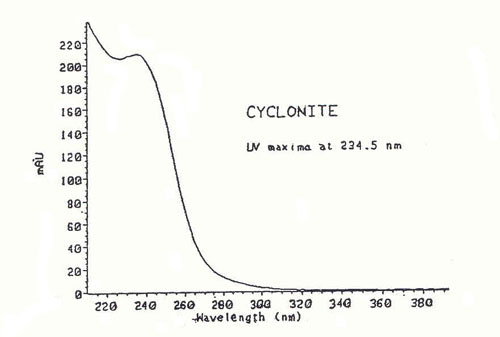

| Structural formula: |

|

1.2 Limit defining parameters

The detection

limit of the analytical procedure is 4.823 ng per injection. This is the

amount of analyte which will give a peak whose height is approximately

five times the baseline noise. 2.

Sampling Procedure

2.1 Apparatus

2.1.1 A personal sampling pump

that can be calibrated to within ±5% of the recommended flow rate with

the sampling device in line.

2.1.2 A 37-mm glass fiber

filter mounted in a polystyrene cassette (with backup

pad). 2.2

Reagents

No sampling reagents are required.

2.3

Sampling technique

2.3.1 Immediately before sampling, remove the

plastic plugs

from the filter cassette.

2.3.2 Attach

the cassette to the sampling pump with flexible tubing and place the

cassette in the worker's breathing zone in such a manner that it does

not impede work performance.

2.3.3 After sampling for the

appropriate time, remove and seal cassette with plastic end

caps.

2.3.4 Wrap each sample end-to-end with an OSHA seal

(Form 21).

2.3.5 Submit at least one blank with each set

of samples. Handle the blank the same as the other samples but do not

draw air through it.

2.3.6 Submit any bulk samples in a

separate container. Do not ship them with the air

samples. 2.4 Extraction

efficiencies

Nine glass fiber filters were each liquid spiked

with a solution of RDX at a concentration of 4.859 mg/mL. Three filters

were each liquid spiked with 18 µL (.5x PEL) of RDX standard. A second

group of three filters were each liquid spiked with 38 µL (lx PEL) of

RDX standard. A third group of three filters were each liquid spiked

with 76 µL (2x PEL) of RDX standard. These filters were allowed to sit

overnight on a desk at ambient temperature and then extracted with 3.0

mL of acetonitrile and analyzed as in Sections 3.4 and 3.5.

Table

2.4

Glass Fiber Filter Extraction Study

|

| Filters |

.5x |

1x |

2x |

|

F1

F2

F3 |

100.3%

100.4%

90.0% |

106.8%

97.3%

104.5% |

95.3%

101.1%

91.2% |

|

| Averages |

96.9% |

102.9% |

95.9% |

2.5 Retention efficiency

Five glass fiber

filters were each liquid spiked with 76 µL (2x PEL) of a 4.859 mg/mL

solution of RDX standard. One hundred twenty liters of humid air

(approximately 70% relative humidity) were drawn through each of four

filters. The fifth filter had 285 liters of humid air drawn through it

and had a recovery of 101.9% All five of these filters were then

extracted and analyzed as in Sections 3.4 and 3.5.

Table

2.5

Retention Efficiency Study

|

| Filters # |

Recovery |

|

RET1

RET2

RET3

RET4 |

107.0%

99.5%

98.3%

89.7% |

|

| Average

recovery is 98.6% |

2.6 Sample storage

Eighteen glass fiber

filters were each liquid spiked with 38 µL (lx PEL) of a 4.859 mg/mL

solution of RDX. One hundred twenty liters of humid air (approximately

70% relative humidity) were drawn though each filter. Half of the

filters were stored in a drawer at ambient temperature, and the other

half were stored in a refrigerator (2°C). They were stored according to

Table 2.6 and extracted and analyzed as in Sections 3.4 and

3.5.

Table

2.6

Storage Study

|

| Days |

Ambient |

Averages |

Refrigerator |

Averages |

|

| 0 |

99.9% |

|

103.2% |

|

| |

99.7% |

|

108.9% |

|

| |

102.9% |

100.8% |

108.4% |

106.8% |

| 7 |

97.6% |

|

100.8% |

|

| |

103.3 |

|

94.9% |

|

| |

96.1% |

99.0% |

97.7% |

97.8% |

| 15 |

97.7% |

|

95.5% |

|

| |

95.7% |

|

98.4% |

|

| |

91.4% |

94.9% |

98.3% |

97.4% |

|

| Average

recovery (ambient) 98.2% |

| Average

recovery (refrigerator)100.7% |

2.7 Recommended air volume and sampling rate.

2.7.1 The recommended air volume

is 120 L.

2.7.2 The recommended flow rate is 1.0

L/min. 2.8 Interferences

(sampling)

It is not known if any compounds will interfere with

the collection of RDX. Suspected interferences should be reported to the

laboratory with submitted samples. HMX (also an explosive) is a

contaminant of and associated with RDX manufacturing and

collection.

2.9 Safe precautions (sampling)

2.9.1 Attach the sampling

equipment in such a manner that it will not interfere with work

performance or employee safety.

2.9.2 Follow all safety

practices that apply to the work area

being

sampled. 3.

Analytical Procedure

3.1 Apparatus

3.1.1 An HPLC equipped with a UV

detector and a manual or automatic injector. A Waters 600 pump, Waters

712 autosampIer and Waters 490E UV detector were used in this

evaluation.

3.1.2 An HPLC column capable of separating

RDX from any interferences. A (25 cm x 4.6 mm i.d.) Econosphere CN

(5-micron) column was used in this evaluation.

3.1.3 An

electronic integrator or other suitable means of measuring detector

response. A Hewlett-Packard 3357 data system was used in this

evaluation.

3.1.4 Vials, 4-mL glass including septa lined

with polytetrafluoroethylene (PTFE).

3.1.5 Volumetric

flasks, pipets, and syringes. 3.2 Reagents

3.2.1 Acetonitrile,

Tetrahydrofuran, HPLC grade.

3.2.2 Water, BPLC grade. A

Millipore Milli-Q system was used to prepare the water in this

evaluation.

3.2.3 RDX. A 91% pure standard with 9%

MIL-C4408 desensitizer was used in this

evaluation. 3.3 Standard

preparation

Prepare stock standard solutions by adding

tetrahydrofuran to preweighed amounts of RDX. Prepare working range

standards by diluting stock solutions with acetonitrile. Store stock and

dilute standards in a freezer.

3.4 Sample

preparation

3.4.1 Transfer glass fiber

filter from the cassette to a 4-mL vial.

3.4.2 Add 3.0 mL

of acetonitrile to each vial.

3.4.3 Seal the vials with

PTFE-lined septa and shake them for half an hour on a mechanical

shaker. 3.5

Analysis

3.5.1 Liquid chromatographic

conditions

Column:

|

25 cm x 4.6 mm i.d. stainless

steel

column packed with 5 micron Econosphere CN |

| |

|

| Mobile Phase: |

42% acetonitrile / 58% water |

| |

|

| Flow rate: |

1 mL/min |

| |

|

| UV detector: |

230 nm |

| |

|

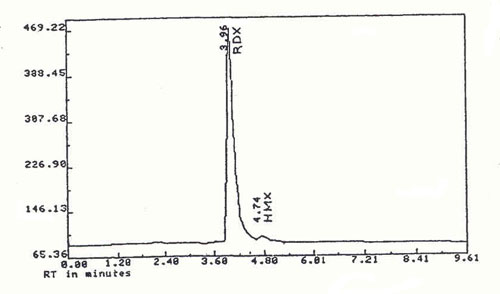

| Retention time: |

3.96 min |

| |

|

| Injection volume: |

10

µL |

3.5.2

Chromatogram (See Figure 2) 3.6 Interferences (analytical)

3.6.1 Any compound having a

retention time similar to that of the analyte is a potential

interference. Generally, chromatographic conditions can be altered to

separate interferences from the analyte. HMX is a possible

interference with RDX and must be separated from

it.

3.6.2 Retention time on a single column is not proof

of chemical identity. Analysis by an alternate HPLC column, detection

at another wavelength (for comparison of absorbance response ratios)

and confirmation by mass spectrometry are additional means of

identification. 3.7

Calculations

3.7.1 Construct a calibration

curve by plotting detector response versus standard

concentration.

3.7.2 Determine the concentration of RDX

in each sample from the calibration curve. If RDX is found, make blank

corrections.

3.7.3 Determine the air concentration by the

following formula.

| |

(µg/mL in sample) x (desorption volume,

mL) |

| mg/m3 = |

|

| |

(air volume, L) x (desorption efficiency,

decimal) |

3.8 Safety precautions (analytical)

3.8.1 Avoid exposure to all

standards.

3.8.2 Avoid exposure to all

solvents.

3.8.3 Wear safety glasses at all times.

4. Recommendations for

Further Study

4.1 A better desorption solvent than acetonitrile

might be found.

4.2 This method should be fully validated

for the following group of polynitro explosives: HMX, RDX, TETRYL, TNT,

2,4-DNT, and 2,6-DNT. It has been shown that all of the above analytes

can be separated from each other by HPLC.

Figure 1. UV Spectrum of RDX in

Acetronitrile |

Figure

2. Chromatogram of RDX |

5. References

5.1 "Kirk-Othmer Encyclopedia of

Chemical Technology", 3rd ed.; Grayson, K.; John Viley and Sons: New

York, NY, 1980; vol. 9, pp 581-584.

5.2 "Documentation of

the Threshold Limit Values and Biological Exposure Indices," 5th ed.;

American Conference of Governmental Industrial Hygienists: Cincinnati,

OH, 1986; P 221.

5.3 "Documentation of the Threshold Limit

Values", 3rd ed.; American Conference of Governmental Industrial

Hygienists: Cincinnati, OH, 19&1 P 221.

5.4 Patty,

P.A.; "Industrial Hygiene and Toxicology", 2nd ed.; John Vileyand Sons:

New York, NY, 1963; vol. 2, pp 2097-2098.

5.6 "Merck

Index", 10th ed.; Vindholz, M., Ed.; Merck and Co.: Rahway, NJ, 1983; P

393.

|