1. General Discussion

1.1 Background

1.1.1 History of

Procedure.

Recently, the OSHA Analytical Laboratory received a

set of field samples requesting analysis for Acid Blue 9. The air

samples had been collected on glass fiber filters, at 1 Lpm for a

total of about 90 liters air. This report describes the analytical

procedure developed and the preliminary validations of the sampling

method.

Acid Blue 9 is a widely used food dye. There has been

many schemes proposed for the qualitative analysis of food dyes, most

of which depended on paper and thin-layer chromatography. Less

attention has been given to the quantitative analysis of dyes. Some of

the methods attempted were: (a) comparison of spot intensities

on TLC plates with those of a range of standards, (b)

spectrophotometric quantitation, (c) titration with titanous chloride

solution, and (d) electrophoresis on polyacrylamide gel. More

recently, HPLC has been applied for dye analysis, using anion-exchange

columns or, more satisfactorily, by ion-pairing. Paired-ion HPLC

affords a means of separating a mixture of food dyes in a single run

(Ref. 5.2.). Preliminary search did not reveal an air sampling method

for Acid Blue 9. Judging from its physical properties, glass fiber

filters may be a suitable collection medium.

1.1.2 Toxic

Effects.

(This section is for information only and should not

be taken as the basis of OSHA policy.)

Acid Blue 9 is

carcinogenic in rats after its subcutaneous injection: it produced

fibrosarcomas following repeated injections. It also produced an

increased incidence of kidney tumors in mice after its oral

administration (Ref. 5.1.).

1.1.3 Potential Workplace

Exposure.

Acid Blue 9 is an FDA certified food dye and is used

in such products as gelatin desserts, ice cream and sherbets,

carbonated beverages, dry drink powders, candy and confectionary

products when they do not contain oils and fats, bakery products and

cereal, puddings, aqueous drug solutions, tablets, capsules, bath

salts, and hair rinses (Ref. 5.3.). Acid Blue 9 has been produced in

the U.S. for over sixty years. In 1975, three U.S. companies produced

622,000 Kg of the general dye grade, and another four companies

produced 56,000 Kg of he food, drug, and cosmetic grade (Ref. 5.1.).

Preliminary literature searches did not reveal any estimate on the

extent of worker exposure.

1.1.4 Physical

Properties

Color Index Names: Acid Blue 9, Food Blue 2

Color

Index Number: 42090

Cas Reg. Number: 2650-18-2

(3844-45-9 )

Chem. Abstr. Names:

N-Ethyl-N-(4[(4-(ethyl[(3-sulfophenyl)methyl]amino)

phenyl)-(2-sulfophenyl)methylene]-2,

5-cyclohexadien-1-ylidene)3-sulfobenzenemethanaminium hydroxide

inner salt, disodium salt; C.I. Acid Blue 9, disodium salt; D and C

Blue No.1; D and C Blue No.4; ethyl(4-(p[ethyl (m-sulphobenzyl)amino]-α

-(o-sulphophenyl)benzylidene)-2,5-cyclohexadiene-l-ylidene)- (m-sulphobenzyl) ammonium hydroxide inner salt,

disodium salt; FD and C Blue 1; FD and C Blue. No.1; FDC Blue No.1;

Acid Sky Blue A; Acilan Turquoise Blue AE; A. F. Blue No.1; Aizen

Brilliant Blue FCF; Aizen Food Blue No.1; Alphazurine; Alphazurine

FG; Alphazurine FGND; Amacid Blue FG; Amacid Blue FG Conc; 1206

Blue, 11388 Blue; Blue Dye Number 1 food additive; Brilliant Blue;

Brilliant Blue FCF; Brilliant Blue Lake; Bucacid Azure Blue;

Calcocid Blue EG; Calcocid Blue 2G; Canacert Billiant Blue FCF,

Cogilor Blue 512.12; Cosmetic Blue Lake; Dispersed Blue 12195;

Disulphine Lake Blue EG; Dolkwal Brilliant Blue; Edicol Blue Cl 2;

Edicol Supra Blue E6; Erioglaucine ; Erioglaucine A; Erioglaucine E;

Erioglaucine G; Eriosky Blue; Fenazo Blue XI; Fenazo Blue XR; Food

Blue 1; Hexacol Brilliant Blue A; Hidacid Azure Blue; Intracid Pure

Blue L; Kjtoc Blue AR; Kiton Pure Blue L; Maple Brilliant Blue FCF;

Merantine Blue EG; Neptune Blue BRA; Concentration; Patent Blue AE;

Patent Blue 2Y; Peacock Blue X-1756; Usacert Blue No.1; Xylene Blue

VSG. Appearance:

Reddish-violet powder or granules with a metallic

luster.

Spectroscopy Data: λ max 630 nm.

Chemical Formula and Molecular

Weight:

| Solubility: Soluble in water and ethanol;

insoluble in vegetable oils.

1.2 Limit Defining Parameters

1.2.1 Detection Limit of the

Analytical Procedure

The detection limit of the analytical

procedure is 0.83 ng Acid Blue 9 per injection. This is the amount of

analyte which will give a peak whose height is approximately five

times the amplitude of the baseline noise. See Figure

1.

1.2.2 Detection Limit of the Overall

Procedure

The detection limit of the overall procedure is

estimated to be 0.2 µg per sample or 0.002 mg/cu m based on the

recommended air volume, assuming 100% recovery from the sampling

device. The recovery test at this level has not been

performed.

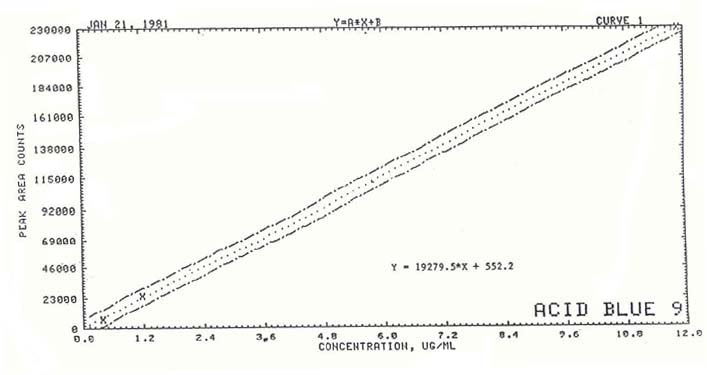

1.2.3 Sensitivity

The sensitivity of

the analytical procedure over a concentration range of 0.395 to 11.9

µg/mL is 19,280 area units per µg/mL of Acid Blue 9. The sensitivity

is determined by the slope of the calibration curve. See Figure

2. 1.3

Advantages

The analytical procedure is rapid, sensitive, and

reproducible.

1.4 Disadvantages

The method has not

been fully validated. 2.

Sampling Procedure

2.1 Apparatus

2.1.1 An air sampling pump with

a flow rate which can be calibrated to within ±5% of the recommended 1

Lpm flow rate while the sampler is in line.

2.1.2 Glass

fiber filter, 37-mm diameter, Gelman Type A, or

equivalent.

2.1.3 Filter holder for 37-mm filters,

Millipore M000037AO, or equivalent. 2.2 Sampling Technique

2.2.1 Assemble the filter in the

two-piece cassette holder and close firmly. The filter is supported by

a backup pad. Secure the cassette holder together

with

tape.

2.2.2 Attach the outlet of the filter cassette to

the personal sampling pump inlet with flexible

tubing.

2.2.3 Air being sampled should not pass through

any hose or tubing before entering the filter

cassette.

2.2.4 A sample size of 100 liters is

recommended. Sample at a flow rate of 1.0 liter/minute. The flow rate

should be known with an accuracy of ±5%.

2.2.5 With each

batch of samples, submit a blank filter from the same lot of filters

used for sample collection. This filter must be subjected to exactly

the same handling as the samples except that no air is drawn through

it. Label this filter as the blank.

2.2.6 The cassette

should be shipped in a suitable container designed to prevent damage

in transit. The samples should be shipped to the laboratory as soon as

possible.

2.2.7 A sample of the bulk material should be

submitted to the laboratory in a glass container with a Polyseal cap.

Never transport, mail, or ship the balk sample in the same container

as the sample or blank filter. 2.3 Retention Efficiency

Two glass fiber

filters were spiked with 1.1.5 µg of Acid Blue 9. Humid air (87%

relative humidity) 140 liters was drawn through the filters at 1 Lpm.

The average recovery of the two filters was 101%.

| Sample |

Spiked Amount |

Treatment |

Peak Height |

Recovery |

|

YC5

YC6

YC7

YC8 |

41.5 µg on GFF

41.5 µg on

GFF

41.5 µg; control

41.5 µg; control |

140 L humid air

140 L humid

air

none

none |

138.0 mm

131.5 mm

131.0

mm

136.0 mm |

103.4%

98.5%

----

---- |

|

|

Average

recovery 100.9% |

2.4 Extraction Efficiency

The average

extraction efficiency from the glass fiber filters spiked with 41.5 µg

of Acid Blue 9 was 95.9%.

| Sample |

Spiked Amount |

Peak Height |

Recovery |

|

YC3

YC4

YC7

YC8 |

41.5 µg on GFF

41.5 µg on

GFF

41.5 µg; control

41.5 µg; control |

126.5 mm

129.5 mm

131.0

mm

136.0 mm |

94.8%

97.0%

----

---- |

|

|

Average

recovery 95.9% |

2.5 Storage

Two glass fiber filters were

spiked with 41.5 µg of Acid Blue 9 and stored at room temperature in the

dark for two days. The average recovery was 100.2%.

| Sample |

Spiked Amount |

Storage Days |

Peak Height |

Recovery |

|

YC3

YC4

YC7

YC8

YC1

YC2

YC7

YC8 |

41.5 µg

41.5 µg

41.5

µg

41.5 µg

41.5 µg

41.5 µg

41.5 µg

41.5 µg |

0

0

control

control

2

2

control

control |

126.5 mm

129.5 mm

131.0

mm

136.0 mm

168.0 mm

157.0 mm

162.0 mm

158.0

mm |

94.8%

97.0%

----

----

105.0%

98.1%

----

---- |

2.6 Recommended Air Volume and Sampling Rate

2.6.1 The recommended air volume

is 100 liters.

2.6.2 The recommended sampling rate is 1

Lpm. 2.7

Interferences

There are no known interferences associated with

the sampling procedure.

2.8. Safety Precautions

2.8.1 Attach the sampling

equipment to the worker in such a manner that it will not interfere

with work performance or safety.

2.8.2 Follow all safety

practices that apply to the work area being sampled

3. Analytical

Method

3.1 Apparatus

3.1.1 High performance liquid

chromatograph equipped with pump, sample injector, variable wavelength

detector, chart recorder, and other necessary

hardware.

3.1.2 HPLC reverse phase C18 analytical column.

Dupont Zorbax ODS column was used for this study.

3.1.3

An electronic integrator or other suitable method to measure detector

response.

3.1.4 Microliter syringe or automatic sampling

device for making sample injections.

3.1.5 Volumetric

flasks of convenient sizes for preparing standards.

3.1.6

Shaking device for extraction of samples. 3.2 Reagents

3.2.1 Acid Blue 9

(Erioglaucine)

3.2.2 Tetrabutylammonium phosphate,

reagent grade

3.2.3 Methanol, HPLC

grade

3.2.4 Water, HPLC grade

3.2.5

Phosphoric Acid 3.3 Sample

Preparation

3.3.1 Remove the filter form the

cassette clean tweezers and place it in a 20-mL scintillation

vial.

3.3.2 Add 5 mL of methanol/water (1:1) to the vial

and cap it.

3.3.3 Shake the vials vigorously on a shaker

for 30 minutes. 3.4

Standard Preparation

3.4.1 Standard of Acid Blue 9 is

prepared by dissolving 8 to 12 mg (accurately weighed) of Acid Blue 9

in water in a 10-mL volumetric flask and making it

to

volume.

3.4.2 Dilute to the working range of 0.1 to

12 µg/mL with water.

3.4.3 Store standards in dark

bottles under refrigeration. 3.5 Analysis

3.5.1 HPLC

Conditions

| Column: |

Zorbax ODS (25 cm x 4.6 mm) |

| Mobile phase: |

55% methanol, 45% water, 0.005 M

tetrabutylammonium phosphate |

| Flow Rate: |

1.0 mL/minute |

| Variable Wavelength Detector: |

650 nm |

| Injection Volume: |

20 µL |

| Retention Time: |

7.8

minutes |

3.5.2

Chromatogram

See Figure 1.

3.5.3. Peak magnitude is

measured by electronic integrator or other means.

3.5.4

An external standard procedure is used to prepare a calibration curve

from the analysis of at least three different concentrations from two

separate

weighings.

3.5.5 Bracket the sample with

analytical standards. 3.6

Interferences (Analytical)

3.6.1 Any collected compound

that has the same LC retention time as analyte and absorbs at 650 nm

is an interference.

3.6.2 HPLC parameters may be varied

to circumvent most interferences.

3.6.3 Retention time

alone is not proof of a chemical identity. Confirmation by other means

should be sought when possible. 3.7 Calculations

3.7.1 The integrator value in

area units for each standard is plotted against its concentration in

µg/mL and a calibration curve using the best fit straight line through

the points is obtained.

3.7.2 Sample concentration is

calculated from the calibration curve.

3.7.3 The air

concentration of Acid Blue 9 for a sample is calculated by the

following equation:

| mg/m3

= |

(µg/mL in

sample)(extraction volume, mL)

(Air volume, L) |

3.8 Safety Precautions

3.8.1 Confine the use of

solvents to a fume hood.

3.8.2 Wear safety glasses in all

laboratory areas. 4.

Recommendations for Further Study

4.1 Preparation of pure

standard

The commercially available Acid Blue 9 is not pure. The

U.S. specification for the food grade is 85% minimum. Purification of

the standard should be attempted either by preparative TLC or

preparative HPLC.

Figure

1. Chromatogram of Acid Blue 9 at Target Concentration and at

Detection Limit. |

Figure 2. Calibration of Acid Blue

9. |

5.

References

5.1 WHO, International Agency for

Research on Cancer, IARC Monograph on the Evaluation

of the Carcinogenic Risk of Chemicals to Man. Some Aromatic Amines and

Related Nitro Compounds -- Hair Dyes, Colouring Agents and Miscellaneous

Industrial Chemicals. Vol. 16, pp. 171-86.

5.2 J.

Chudy, N.T. Crosby, and I. Patel, J. Chromatogr., 154, (1978), p

306-312.

5.3 A Standen, ed., Kirk-Othmer

Encyclopedia of Chemical Technology, Second Ed., Vol. 5, pp.

865-66. Interscience Publishers, New York, N.Y.,

1963.

|