1. General Discussion

1.1 Background

1.1.1 History of procedure This evaluation was undertaken

to determine the effectiveness of the OVS-2 tube as a sampling diuron

and to analyze samples. It follows the developed for carbaryl. (Ref.

5.1)

1.1.2 Toxic effects (This section is for information

only and should not be taken as the basis of OSHA policy). Herbicides

are weed killers with either general or selective applications in

agriculture. Herbicides interfere with plant chemistry and physiology.

They may inhibit plant respiration and photosynthesis, as well as

plant physiology by mimicking growth regulators or interfering with

their synthesis or action. Diuron is a herbicide whose chemical class

is phenyl urea. It has been shown to inhibit plant photosynthesis by

blocking light reaction II. Hence light is required to elicit its

phytotoxic effects. This herbicide demonstrates low acute toxicity

toward mammals. (Ref.

5.2) The following paragraph describing the toxicity is excerpted

from the book Documentation of the Threshold Limit

Values And Biological Exposure Indices (Ref.

5.3)

Hodge and co-workers have reported a low order of acute

and chronic toxicity for diuron. The oral LD5O for male

rats was given at 3400 mg/kg. No -effect dietary concentration

levels in two-year feeding studies are considered to be 250 ppm for

rats and 125 ppm for dogs. A dietary concentration of 125 ppm did

not adversely affect reproduction in a three-generation rat study.

There was no evidence of carcino genicity in these chronic studies

or in an 18-month study on mice at approximately 1400 ppm.

The following paragraph describing the harm and symptoms

of diuron were taken from the Handbook of Toxic and

Hazardous Chemicals and Carcinogens. (Ref.

5.4)

The concentrated material may cause irritation to the

eyes and mucous membranes, but a 50% water paste was not irritating

to the intact skin of guinea pigs. Due to these factors diuron has

been given a TLV-TWA of 10 mg/m3 by the ACGIH. (Ref.

5.3) OSHA adopted this same value as its PEL in

March 1989.

Editorial Note: These March 1989 PELs were vacated on

July 7, 1992 and ceased to be enforceable on March 23, 1993 (FR

58:35338-35351, 6/30/1993).

1.1.3 Potential workplace

exposure No estimate of worker exposure to diuron could be

found. Potential exposure involves those individuals in manufacturing,

formulation, and application of the herbicide. (Ref.

5.4) 1.1.4 Physical Properties (Ref.

5.2-5.7)

| Molecular weight: |

233.10 |

| Molecular Formula: |

C9H10Cl2N2O |

| CAS #: |

330-54-1 |

| IMIS #: |

2684 |

| Melting point: |

158 to 159°C |

| Vapor Pressure: |

0.0041 Pa (0.000031 mmHg)

at 30°C |

| Appearance: |

white crystalline

solid |

| Solubility: |

42 ppm in water at 25°C,

5.3% at 27°C, very low so'. hydrocarbon solvents |

| Synonyms: |

Cekiuron, Crisuron,

Dailon, Diater Di-on, Direx4L, Diurex, Diurol Dynex, Karmex, Rout,

Unidron, Urox Vonduron, dichlorfenidim (USSR) |

| Chemical names: |

3-(3,4-Dichlorophenyl)-1,1-dimethylurea;

N'-(3,4-dichlorophenyl)-N,N-dimethylurea |

| UV spectrum: |

|

| Stability: |

Sunlight (ultraviolet

irradiation) degrades diuron. Decomposes on heating

(180-190°C) yielding dimethylamine and

3,4-dichlorophenylisocyanate. |

Structural Formula:  1.2 Limiting defining parameters The detection limit of

the analytical procedure is 1.81 ng per injection. This is the amount of

amount of analyte which will give a peak whose height is approximately

five times the baseline noise. 2.

Sampling Procedure

2.1 Apparatus

2.1.1 A personal sampling pump that

can be calibrated to within ±5% of the recommended flow rate with the

sampling device in line.

2.1.2 OVS-2 tubes, which

are specially made 13-mm tubes o.d. glass tubes that are tapered to

6-mm o.d. They are packed with a 140-mg backup section and a 270-mg

sampling section of cleaned XAD-2. The backup section is retained by

two foam plugs and the sampling section is between one foam plug and a

13-mm diameter glass fiber filter. The glass fiber filter is held next

to the sampling section by a polytetrafluoroethylene (PTFE) retainer.

polytetrafluoroethylene (PTFE)

retainer | 2.2 Reagents

No sampling reagents are

required. 2.3 Sampling

Technique

2.3.1 Attach the small end of the

OVS-2 sampling tube to the sampling pump with flexible, plastic tubing

such that the large, front section of the sampling tube is exposed

directly to the atmosphere. Do not place any tubing in front of the

sampler.

2.3.2 Attach the sampler vertically (large end

down) in the worker's breathing zone in such a manner that it does not

impede work performance.

2.3.3 After sampling for the

appropriate time, remove the sampling device and seal the tube with

plastic end caps.

2.3.4 Wrap each sample end-to-end with

an OSHA seal (Form 21).

2.3.5 Submit at least one blank

with each set of samples. Handle the blank the same as the other

samples but do not draw air through it. 2.3.6 Submit any bulk

samples in a separate container. Do not ship them with the air

samples. 2.4 Extraction

efficiency Three OVS-2 tubes were each liquid spiked with 31 µL (1/20

PEL) of a 0.9627 mg/mL solution of diuron in acetonitrile. Three

additional OVS-2 tubes were each liquid spiked with 62 µL (1/10 PEL) of

the above diuron standard. These tubes were allowed to sit overnight on

a desk at ambient temperature and then extracted with 5.0 mL of

acetonitrile and analyzed as in Sections 3.4 and

3.5.

Table

2.4

OVS-2 Extraction Study

|

| Tubes # |

1/20 PEL |

1/10 PEL |

|

|

|

| OVS1 |

96.6% |

86.6% |

| OVS2 |

88.1% |

96.3% |

| OVS3 |

91.7% |

95.0% |

|

| Averages |

92.1% |

92.6% |

2.5

Retention efficiency Four OVS-2 tubes were each liquid spiked with 62 µL

of a 0.9627 mg/mL solution of diuron by spiking the glass fiber filter.

Sixty liters of humid air (approximately 70% relative humidity) were

drawn through each tube. Three of these tubes were then desorbed and

analyzed as in Sections 3.4 and 3.5. No diuron was recovered from the

backup section of these tubes. The fourth tube had 120 liters of humid

air drawn through it and had a recovery of 91.9%.

Table 2.5

Retention Efficiency Study |

| Tube # |

Recovery |

| RET1 |

95.6% |

| RET2 |

91.0% |

| RET3 |

95.5% |

|

| Average recovery is 94.0% |

2.6 Sample storage

Eighteen OVS-2 tubes were each

liquid spiked with 62 µL of a 0.9627 mg/mL solution of diuron by placing

it on the glass fiber filter. Sixty liters of humid air (approximately

70% relative humidity) were drawn through each tube. Half of the tubes

were stored in a drawer at ambient temperature, and the other half were

stored in a refrigerator (2°C). They were stored according to Table 2.6

and extracted and analyzed as in Section 3.4 and 3.5. No diuron was

recovered from the backup section of these tubes.

Table

2.6

Storage Study

|

| Days |

Ambient |

Averages |

Refrigerator |

Averages |

|

|

|

|

|

| 0 |

95.7% |

96.2% |

96.2% |

96.3% |

|

97.1% |

|

96.7% |

|

|

95.9% |

|

96.1% |

|

|

|

|

|

|

| 7 |

94.2% |

94.4% |

95.3% |

95.0% |

|

93.3% |

|

95.0% |

|

|

95.6% |

|

94.8% |

|

|

|

|

|

|

| 14 |

94.1% |

92.5% |

96.2% |

95.7% |

|

91.6% |

|

95.8% |

|

|

91.7% |

|

95.0% |

|

|

Average

recovery (ambient) 94.4%

Average recover (refrigerator) 95.7%

2.7 Recommended air volume and sampling

rate

2.7.1 The recommended air volume is 60

L.

2.7.2 The recommended flow rate is 1.0 L/min.

2.8 Interferences (sampling)

It

is not known if any compounds will interfere with the collection of

diuron. Suspected interferences should be reported to the laboratory

with submitted samples.

2.9 Safety precautions (sampling)

2.9.1 Attach the sampling equipment in

such a manner that it will not interfere with work performance or

employee safety.

2.9.2 Follow all safety practices that apply

to the work area being sampled. 3. Analytical Procedure

3.1 Apparatus

3.1.1 An HPLC equipped with a UV

detector and a manual or automatic injector. A Waters 600 pump, Waters

712 autosampler and Waters 490E UV detector were used in this

evaluation.

3.1.2 An HPLC column capable of separating diuron

from any interferences. A (8-cm x 6.2-mm i.d.) Golden Series Zorbax

ODS (3 micron) column was used in this evaluation.

3.1.3

An electronic integrator or other suitable means of measuring detector

response. A Hewlett-Packard 3357 Data System was used in this

evaluation.

3.1.4 Vials, 4-mL and 20-mL glass with capped or

PTFE-lined septa.

3.1.5 Volumetric flasks, pipets, and

syringes. 3.2 Reagents

3.2.1 Acetonitrile, HPLC grade.

3.2.2 Water, HPLC grade. A Millipore Milli-Q system was used

to prepare the water in this evaluation.

3.2.3 Diuron. A

99.25% pure standard from EPA was used in this

evaluation. 3.3 Standard

preparation

Prepare stock standard solutions by adding

acetonitrile to pre-weighed amounts of diuron. Prepare working range

standards by diluting stock solutions with acetonitrile. Store stock and

dilute standards in a freezer.

3.4 Sample preparation

3.4.1 Transfer the 13-mm glass fiber

filter and the 270-mg sampling section of the OVS-2 tube to a 20-mL

vial. Place the first foam plug and the 140-mg backup section in a

separate vial. A small glass funnel can be used to facilitate the

transfer of the adsorbent. Discard the rear foam plug. Do not discard

the glass sampling tube; it can be reused.

3.4.2 Add 5.0 mL of

acetonitrile to each vial.

3.4.3 Seal the vials and shake them

for half an hour on a mechanical shaker.

3.4.4 Transfer an

aliquot of sample to the 4-mL vial and seal with PTFE-lined

septa. 3.5 Analysis

3.5.1 Liquid chromatographic

conditions

| Column: |

8-cm x 6.2-mm i.d.

stainless steel Golden Series column packed with 3 micron Zorbax

ODS |

| Mobile Phase: |

55% acetonitrile / 45%

water |

| Flow Rate: |

1 mL/min |

| UV detector: |

254 nm |

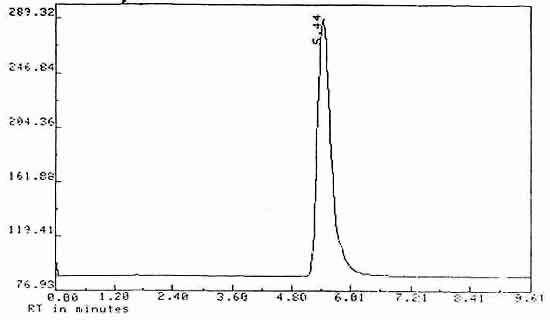

| Retention time: |

5.44 min |

| Injection volume: |

15

µL |

3.5.2

Chromatogram

Figure 3. Chromatogram of Diuron

|

3.6 Interferences (analytical)

3.6.1 Any compound having a retention

time similar to that of the analyte is a potential interference.

Generally, chromatographic conditions can be altered to separate

interferences from the analyte.

3.6.2 Retention time on a

single column is not proof of chemical identity. Analysis by an

alternate HPLC column, detection at another wavelength (for comparison

of absorbance response ratios) and confirmation by mass spectrometry

are additional means of identification. 3.7 Calculations

3.7.1 Construct a calibration curve by

plotting detector response versus standard concentration.

3.7.2 Determine the concentration of diuron in each sample

from the calibration curve. If diuron is found on the backup section,

make blank corrections for each section separately before adding the

results together.

3.7.3 Determine the air concentration by the

following formula.

| mg/m3 = |

(µg/mL, blank corrrected) x

(desorption volume, mL)

(air volume, L) x (desorption efficiency, decimal)

|

3.8

Safety precautions (analytical)

3.8.1 Avoid exposure to all standards.

3.8.2 Avoid exposure to all solvents.

3.8.3 Wear

safety glasses at all times. 4. Recommendations for Further Study

4.1 A better desorption solvent than

acetonitrile might be found.

4.2 This method should be fully

validated.

4.3 This method has been partially evaluated at 60

liters or air at 1 liter per minute; however, since the PEL of diuron is

high and its solubility is low, it might be better to lower the sampling

rate to 200 cc/min to prevent the sampling tube from becoming clogged

with diuron.

5. References

5.1 Burright, D.; Method #63,

"Carbaryl"; OSHA Analytical Laboratory unpublished, 1987.

5.2

Cawse, J.N.; "Kirk-Othmer Encyclopedia of Chemical Technology", 3rd ed.;

John Wiley and Sons: New York, NY., 1980; Vol. 12, pp 297-322.

5.3 Documentation of the Threshold Limit Values and Biological

Exposure Indices", 5th ed.; American Conference of Governmental

Industrial Hygienists: Cincinnati, OH, 1986; p 228.

5.4 Sittig,

M.; "Handbook of Toxic and Hazardous Chemical and Carcinogens", 2nd ed.;

Noyes Publication: Park Ridge, NJ., 1985; p 394.

5.5 "Farm

Chemicals Handbook"; Meister Publishing Co.: Willoughby, OH, 1986; p

C88.

5.6 "Merck Index", 10th ed.; Windholz, M., Ed.; Merck and

Co.: Rahway, NJ, 1983; p 494.

5.7 Cawse, J.N.; "Kirk-Othmer

Encyclopedia of Chemical Technology", 3rd ed.; John Wiley and Sons: New

York, NY., 1980; vol. 21 pp 273-276.

|