- History

When a trench or other excavation is

made in soil, the residual forces in the ground work to restore the soil

to a more stable configuration. If those residual forces (gravity) are

greater than those holding the trench or excavation walls where they

are, a cave-in occurs. There are a number of factors which determine the

stability of a given excavation wall. It is beyond the scope of this

document to fully describe soil mechanics in this way. However, it has

been found empirically that soil, when sloped appropriately, will resist

the residual forces and remain safely stable.

Because the

evaluation of soil conditions and structure is crucial to safe operation

in and around excavations, an excavation standard was among the first

promulgated by OSHA in 1971. In that standard, soils were classified

into three types called running, unstable, and hard compact (Ref. 3.2).

These terms were generally misunderstood. Later, the terms were revised

and renamed granular, cohesive, granular cohesionless, and cemented

(Ref. 3.1).

In 1989, it was estimated that there were 70

fatalities and more than 800 lost workday injuries annually in the

United States due to excavation accidents. Responding to this high

incidence rate, OSHA promulgated the current excavation standards (Ref

3.1) and it has the following requirements:

- Classification of soil and rock deposits. Each soil and rock

deposit shall be classified by a competent person as Stable Rock, Type

A, Type B, or Type C in accordance with the definitions set forth in

29 CFR 1926 Subpart P Appendix A.

- Basis of classification. The classification of the deposits shall

be made based on the results of at least one visual and at least one

manual analysis. Such analyses shall be conducted by a competent

person using tests described in 29 CFR 1926 Subpart P Appendix A, or

in other recognized methods of soil classification and testing such as

those adopted by the American Society for Testing Materials, or the

U.S. Department of Agriculture textural classification system.

- Visual and manual analyses. The visual and manual analyses, such

as those noted as being acceptable in 29 CFR 1926 Subpart P Appendix

A, shall be designed and conducted to provide sufficient quantitative

and qualitative information as may be necessary to identify properly

the properties, factors, and conditions affecting the classification

of the deposits.

- Layered systems. In a layered system, the system shall be

classified in accordance with its weakest layer. However, each layer

may be classified individually where a more stable layer lies under a

less stable layer.

- Reclassification. If, after classifying a deposit, the properties,

factors, or conditions affecting its classification change in any way,

the changes shall be evaluated by a competent person. The deposit

shall be reclassified as necessary to reflect the changed

circumstances.

As a result of the new

regulations, the Bureau of Labor Statistics reported, in 1999, 44 deaths

due to excavation and trenching accidents. (Ref. 3.10)

The angle

of the slope depends upon the properties of the soil in which the

excavation has been made. The mineral particles that constitute soil and

other earth materials can bond by chemical and physical forces that

oppose the force of gravity. Chemical bonding, or cohesion, refers to

the chemical forces that bond mineral particles. Physical bonding refers

to the bonding of the more coarse grains such as sand and gravel by

frictional forces that include the interlocking of particles.

29

CFR 1926 Subpart P Appendix A is based on site and environmental

conditions, and on the structure and composition of the soil deposits.

The soil classification system means a method of categorizing soil and

rock deposits in a hierarchy of Stable Rock, Type A, Type B, and Type C,

in decreasing order of stability.

- Stable rock means natural solid mineral matter that can be

excavated with vertical sides and remain intact while

exposed.

- Type A means cohesive soils with an unconfined, compressive

strength of 1.5 ton per square foot (tsf) (144 kPa) or greater.

Examples of cohesive soils are: clay, silty clay, sandy clay, clay

loam and, in some cases, silty clay loam and sandy clay loam. Cemented

soils such as caliche and hardpan are also considered Type A. However,

no soil is Type A if:

- The soil is fissured; or

- The soil is subject to vibration from heavy traffic, pile

driving, or similar effects; or

- The soil has been previously disturbed; or

- The soil is part of a sloped, layered system where the layers

dip into the excavation on a slope of four horizontal to one

vertical (4H:1V) or greater; or

- The material is subject to other factors that would require it

to be classified as a less stable material.

- Type B means:

- Cohesive soil with an unconfined compressive strength greater

than 0.5 tsf (48 kPa) but less than 1.5 tsf (144 kPa); or

- Granular cohesionless soils including: angular gravel (similar

to crushed rock), silt, silt loam, sandy loam and, in some cases,

silty clay loam and sandy clay loam.

- Previously disturbed soils except those which would otherwise be

classed as Type C soil.

- Soil that meets the unconfined compressive strength or

cementation requirements for Type A, but is fissured or subject to

vibration; or

- Dry rock that is not stable; or

- Material that is part of a sloped, layered system where the

layers dip into the excavation on a slope less steep than four

horizontal to one vertical (4H:1V), but only if the material would

otherwise be classified as Type B.

- Type C means:

- Cohesive soil with an unconfined compressive strength of 0.5 tsf

(48 kPa) or less; or

- Granular soils including gravel, sand, and loamy sand; or

- Submerged soil or soil from which water is freely seeping; or

- Submerged rock that is not stable, or

- Material in a sloped, layered system where the layers dip into

the excavation or a slope of four horizontal to one vertical (4H:1V)

or steeper.

In its 1989 rule

making, OSHA relied heavily on a classification system developed in 1982

by the National Bureau of Standards (now the National Institute of

Standards and Technology - NIST). In addition, OSHA used several other

sources of information including ASTM standards. (Ref. 3.10)

In

addition to these fundamental references, SLTC used The Unified Soil Classification System (Refs. 3.3

and 3.4), the Engineering Geology Field Manual of the

U.S. Bureau of Reclamation (Ref. 3.5), and other documents (Refs.

3.6-3.9) in the development of this method.

OSHA Method ID-194

was developed to emphasize the performance and engineering properties of

soil and is consistent with the objectives and requirements of the 1989

Federal excavation regulations. Many other methods used to classify soil

provide a textural name for soil such as clay, silty clay, sandy clay,

clay loam and, in some cases, silty clay loam and sandy clay loam.

Because each of these methods specify slightly different tests, the

names are similar to each other but can have a different meaning. An

attempt is made to provide a textural name of the soil with this OSHA

method (so that a comparison can be made with other methods) but a

compete separation of all of the soil components is not performed by the

tests described in this method. This could result in a textural name

that is slightly different from other soil classifying methods.

- Analytical

The analytical procedures of this method

are grouped under the headings: visual, manual, and classification. Soil

samples may represent a proposed excavation site or selected areas of an

existing excavation. All samples are analyzed and classified by the

methods outlined and described here.

Safety and health

precautions include care to prevent air-born dust and the use of gloves

and safety glasses when handling wet soil.

2.1 Visual (Ref.

3.1)

Copy all sample identification numbers from the sample

submission report form to sample work data sheets (An example is

included at the back of this method.). For analytical convenience,

accountability, and continuity, record the number of each container used

in analysis.

Open the soil bag and record the general

characteristics of the sample, such as sand, gravel, or clay. Note and

set aside any rock fragments (pieces of rock >3 in.) that may be

present. Estimate the percent of the sample that is in the form of

clumps between ¼ and 1 in., and identify possible structural

discontinuities such as layers, lenses (discontinuous layers) and cracks

or fissures. Note the presence of water or other features that are

peculiar to the sample.

2.2 Manual

The manual tests

include the equipment required for analysis and the procedures used to

determine the specific properties and classification of the

soil.

2.2.1 Equipment

- Bread pans of regular size for drying samples.

- Stainless steel bowls of at least 2- L capacity.

- A forced air oven that will hold and dry samples at 60°C.

- U.S.A. Standard 8-in. dry sieving pans #4 (4.75-mm opening), #40

(0.425-mm opening), a #200 (0.075-mm opening) and a catch pan and

cover.

- A #200 U.S.A. Standard 8-in. wet sieving pan.

- A laboratory balance that will read up to 3 kg with a precision

of ±1.0 g.

- A standard soil pocket penetrometer (Ref. 3.2) for the

measurement of the unconfined compressive strength.

- A fine hair bristle brush and a wire bristle brush for cleaning

the test sieves.

2.2.2 Procedures

- Unconfined Compressive Strength (Ref. 3.1)

Within five

minutes after a sample of broken soil is exposed to the open air,

remove one or more of the largest clumps and analyze it with a

pocket penetrometer. Slice each clump with a spatula to provide a

smooth surface for analysis.

Press the penetrometer cylinder

against the sample and compress the soil and the calibrated spring

of the instrument to the marked ring on the cylinder. Read the

position of the ring on the calibrated scale of the cylinder. Record

the unconfined compressive strength reading in tons per square foot

(tsf) or kilograms per square centimeter (kg/cm2). Report

the average of at least three readings if possible. Note all samples

that break apart and do not provide a positive analysis.

- Plasticity (Refs. 3.3 and 3.4)

Plasticity is defined as

an inherent property of certain soils to mold and roll between the

palms of the hands into a stable thread 0.3 cm ( in.) in diameter

and the tensile strength to support a 5-cm section when held at one

end. To possess plasticity for classification purposes, the soil

must satisfy these conditions and contain at least 15% silt and clay

as determined by gradation analysis.

Determine and record the

state of plasticity of the soil at the as-received water content. If

plasticity is not observed, analyze the sample after it is dried

using only that part of the sample that passes the #40 sieve. Add

water in different amounts to obtain a wide range of water content

for analysis. If the clay content is low, plasticity is not an

inherent property of the soil, and it will not be identified at any

water content.

- Gradation Analysis (Ref. 3.3)

This test is used to

determine the amount of gravel, sand, and total silt and clay in a

soil sample. These constituents are identified using the particle

size scale of the Unified Soil classification system. Silt and clay

are not distinguished from each other in this test. The gradation

procedures are described as follows:

Dry the soil for 2 days

at 60°C to prepare the soil for analysis. Vent the air from the oven

to the outside to avoid exposure to possible toxic

fumes.

Tare a bowl on a laboratory balance. Add at least 100

g of a dry fine-grained sample or 200 g of a coarse-grained sample

(sand and gravel) to the bowl. If that amount is not available, use

as much as possible. Record the weight and cover the sample with

water. Let it stand in this state for at least 2 hours and up to 24

hours.

Transfer this material to a #200 wet sieving pan and

wash the fine grains of silt and clay through the sieve with running

water until it is visibly clear. Wash the material that is retained

on this sieve back into the bowl and decant the water and any

supernatant. Dry this residue at 60°C or at any other preferred

temperature.

Place the dried soil onto a nest of pans

containing a #4 sieve at the top, a #200 sieve in the middle, and a

pan at the bottom to catch any residual silt and clay. Tap the pans

manually on a table top at least 20 times to separate the grains by

size.

Report the total gravel as the weight of material

retained on the top or #4 sieve and the total sand as the weight of

material retained on the next or #200 sieve. The total silt and clay

content is equal to the difference between the combined weight of

the sand and gravel and the weight of the sample used. Silt and clay

comprise the fine-grained material that is washed through the #200

sieve during analysis. Convert the weight of the material retained

on the #4 sieve and the #200 sieve as the dry weight percent of the

gravel and sand, respectively. 2.3 Classification

The analytical data is used to

classify the soil according to the dominate texture, structure, and Type

(strength), the ultimate objective of analysis. These classifications

are identified according to specific conformance and performance

standards and definitions outlined in 29 CFR 1926 Subpart P Appendix A

and the following definitions and instructions:

2.3.1 Structural

Classification

The common soils include those that

correspond to a granular, cohesive, or granular cohesionless

structures outlined in the Federal excavation regulations. They are

identified as follows:

- Granular soil contains <15% silt and clay (>85% sand and

gravel) (Ref. 3.4)

- Cohesive soil possesses the property of plasticity

- Granular cohesionless soil contains >15% silt and clay and

does not possess plasticity, or otherwise, is neither granular nor

cohesive. (Ref. 3.4)

- Fissures are identified visually or indirectly by the tendency

of clay with a Qu >1.5 to break into small pieces

between ¼ and 1 in. due to microfissures when disturbed.

2.3.2 Type

Classification:

- Granular soil is Type C

- Granular cohesionless soil is Type B

- Cohesive soil is Type C if the unconfined compressive strength,

Qu, is <0.5

- Cohesive soil is Type B if Qu is 0.5 to 1.5

- Cohesive soil is Type A if Qu is >1.5 and not

fissured

- Cohesive soil that is fissured is Type B unless the

Qu dictates that it is Type C.

- Fissures may be identified visually or indirectly by the

tendency of clay with a Qu >1.5 break into small

pieces between ¼ and 1 in. due to microfissures when

disturbed.

A more convenient guide to classification is given

in the chart on Page 7. The three soil structures appear at the top

of the chart, and the appropriate definitions and properties that

apply are listed below with Soil Type at the bottom. Soil Structure

and Soil Type systematically unfold accordingly. 2.3.3 Textural Classification

Soil texture is based on the following definitions and

instructions:

- Designate clay as the last word in the textural name of all

soils that are cohesive, and designate sand or gravel as the last

word for all soils that are granular.

- Modify that name with the less predominant constituents as a

first name.

- Do not use either sand or gravel in the textural name if the

soil contains <10% and <30% of the dry weight of the soil,

respectively.

- An example and the most typical of all soils classified at

OSHA-SLTC is sandy clay.

2.3.4

Report

The following information will be

entered onto the sample report in the section titled 'Comments for

Specific Analyte':

Classification:

Textural: xxxx (e.g.,

Sandy Clay)

Structural: xxxx (e.g., Cohesive)

Type: x (e.g.,

B)

The above classification is based on visual/manual procedures

described in OSHA Method ID-194. 2.3.5 Soil Reclassification

Classification of soils by this

method is based upon measurement of physical properties appropriate

to the OSHA excavation standard, and the condition of the sample as

it is received at the Salt Lake Technical Center. Certain field

conditions, such as the presence of standing water, may override

this laboratory classification as mentioned in 29 CFR 1926 Subpart P

Appendix A. Supplemental testing by other methods of analysis may

provide a more appropriate description and classification of unusual

or atypical soils.

SOIL CLASSIFICATION

CHART

|

| Note: |

1) Intact cemented soils such as hardpan

and caliche (a layered carbonate accretion) are classified Type

A.

2) All fissured soils are classified cohesive and Type

B.

3) Angular gravel and rock fragments are classified granular

cohesionless and Type B.

4) The value of 15% in the above chart

corresponds to the maximum amount of silt and clay that is permitted

in a soil that is granular in structure. (Ref.

3.4) |

- References

3.1 Code of Federal Regulations, Title 29, Part

1926, Subpart P, 1999, pp. 372-409. U.S. Government Printing Office,

Washington, D.C. 20402-9328.

3.2 Ibid. 1987, p. 207.

3.3

Earth Manual, U.S. Dept of the Interior, Water

and Power Resources Service, Denver, CO, 1980, pp.1-22.

3.4 U.S.

Bureau of Reclamation, Engineering Geology Field Manual, Volume 1. p.38.

U.S. Government Printing Office, Washington, D.C. 20402-9328.

3.5

Fundamentals of Geotechnical Analysis, Dunn,

I.S., 1980, p.33, John Wiley and Sons, Inc.

3.6 Materials Testing Catalogue, Soiltest Inc.,

Corporate Headquarters, 86 Albrecht Drive, Lake Bluff, Illinois,

60044-8004.

3.7 National Academy of Sciences,

Compendium 13. Slopes: Analysis and Stabilization, 1980, p.141.

Washington, D.C. 20402-9328.

3.8 Mechanics in

Foundation Engineering, Wilun, Z. and Starzewski, K., p.77, 1972,

Surrey Press, 450 Edgeware Rd. London.

3.9 Engineering Classification and Index Properties of Intact

Rock, Deere, D.U., and Miller, R.P.,Clearance House for Federal

Scientific and Technical information, Dept. of Commerce, Washington

D.C.

3.10 Federal Register, Vol. 54,

No. 209 p45894 et seq., U.S. Government Printing Office, Washington,

D.C. 20402-9328

The method for packaging the soil

samples for shipment to the SLTC will be in a sturdy, leak-proof

container, which include the following:

Samples will be placed in a heavy-duty plastic

bag that will not tear and secured and sealed airtight with tape. The

plastic bag will be placed in a heavy-duty cotton bag for additional

protection. Samples will be placed in a heavy-duty plastic

bag that will not tear and secured and sealed airtight with tape. The

plastic bag will be placed in a heavy-duty cotton bag for additional

protection.

- Each soil sample will be sealed for identification with an

official Form 21 seal containing a field number, sampling date and the

sampler's name.

- If the soil sample being shipped from all foreign sources,

including Guam, Hawaii, Puerto Rico, and the U.S. Virgin Islands

through any U.S. port of entry, a PPQ Form 550 will be attached to the

outside of the shipping box. Copies of this form may be obtained by

telephoning 801-524-7900 and asking for the Soils Laboratory. Requests

for the form can also be made by e-mail to merrell.clint@dol.gov or crane.dan@dol.gov.

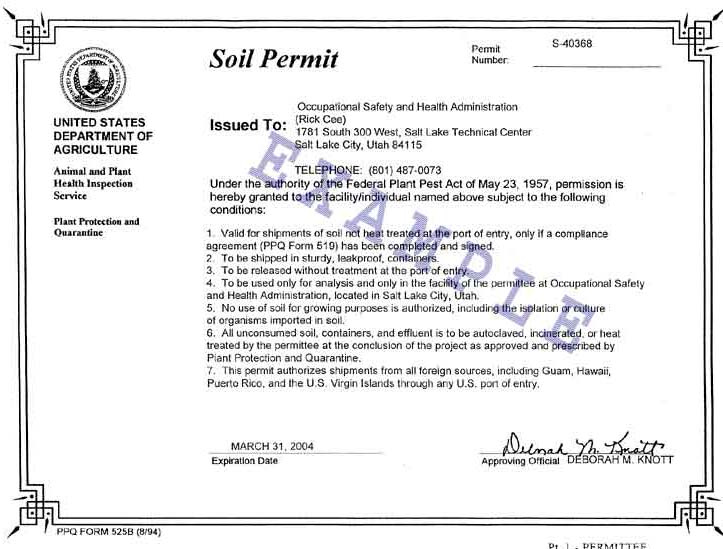

Below

is an example of the Soil Permit that is necessary to import soil

samples into the United States. A copy of the actual permit is to be

attached to the OSHA Form 91A. The permit can be obtained by

contacting the persons mentioned above.

|

Classification of Soils for Excavations

Sample Work

Data Sheet |

Analyst:

|

Sampling Number: |

CSHO ID:

|

Reporting ID: |

Inspection Number: |

Laboratory Number:

|

Submission Number: |

| Sample Description: |

| Compressive Strength (tsf)

(average): |

|

|

|

|

Clumps (estimated):

|

Fissures: |

Yes |

No |

| >1 in. (%): |

Layers or Lenses: |

Yes |

No |

| >¼ in.<1 in. (%): |

Water Present: |

Yes |

No |

| Drying Pan Number: |

|

| Plasticity: |

Yes No |

|

|

|

|

| Graduation Bowl Number: |

Sample Weight (g): |

| >#4 Sieve (g): |

>#200 Sieve (g): |

<#200 Sieve (g): |

| Gravel (%): |

Sand (%): |

Silt & Clay (%): |

| Classification |

| Textural: |

|

| Structural: |

Granular |

Cohesive |

Granular Cohesionless |

| Type: |

A |

B |

C |

Notes:

|

|